How to measure the dimension of tin container or box?

Measuring box size is relatively easy! People usually measure the external dimensions, while it is crucial to accurately measure a custom packaging box because it makes sure the product safety and correct display.

In addition, box dimensions are a critical part of any package as they significantly impact the materials need, cost of production, shipping and warehousing costs.

Before any custom tin packaging ordered, it is essential to get the measurements right.

To help you do that, we have laid out a clear step-by-step guide for finding and measuring dimensions, calculating the volume of a box, and one essential consideration to keep in mind to provide you with the most accurate measurements.

The three dimensions of tin box or container

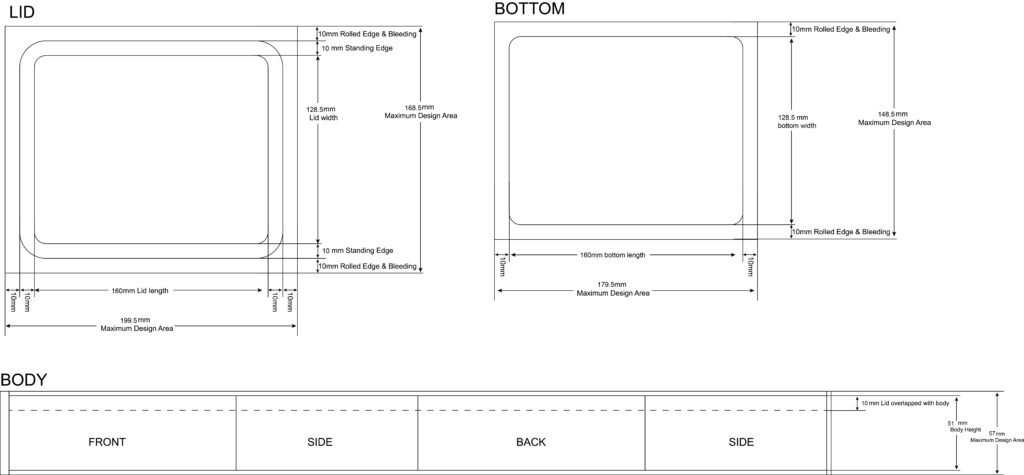

We usually measure a tin box from outside by length, width and height. Tin box is placed vertically and lid up.

Length: The longest side when looking at the top of the box

Width: The shorter side when looking at the top of the box

Depth(Height): The side perpendicular to the lenght and width

Unlike paper box, a key point is that metal tin packaging usually are produced with round corners, sometimes your product size seems ok to filled in while you may ignore tins with round corners.

In addition, different decorative tins with various lid type plug lid, pillow lid, flush lid and bottom structure (rolled tin bottom, rolled outside bottom) which would affect to recognize the exact volume.

Thus, measuring internal dimensions ensures your product can fit inside of the box and is secure. Leaving minimal room for movement inside the package. It is vital that you need to provide the right dimension of your product filled in tin or tell us your application industry, we would provide our professional suggestion and solutions.

Let’s check below different decorative tins measurement

Plug lid, pillow lid, double top lid and more, these lids usually about 5-8mm into the body of tin box.

Different bottom structure occupy the space as well; edge rolled inside bottom, edge rolled outside bottom, special bottom.

Except for above, we need to mention that the box rolled edge is generally about 2mm, then two side totally 4mm. Make sure your product can filled in easily from top.

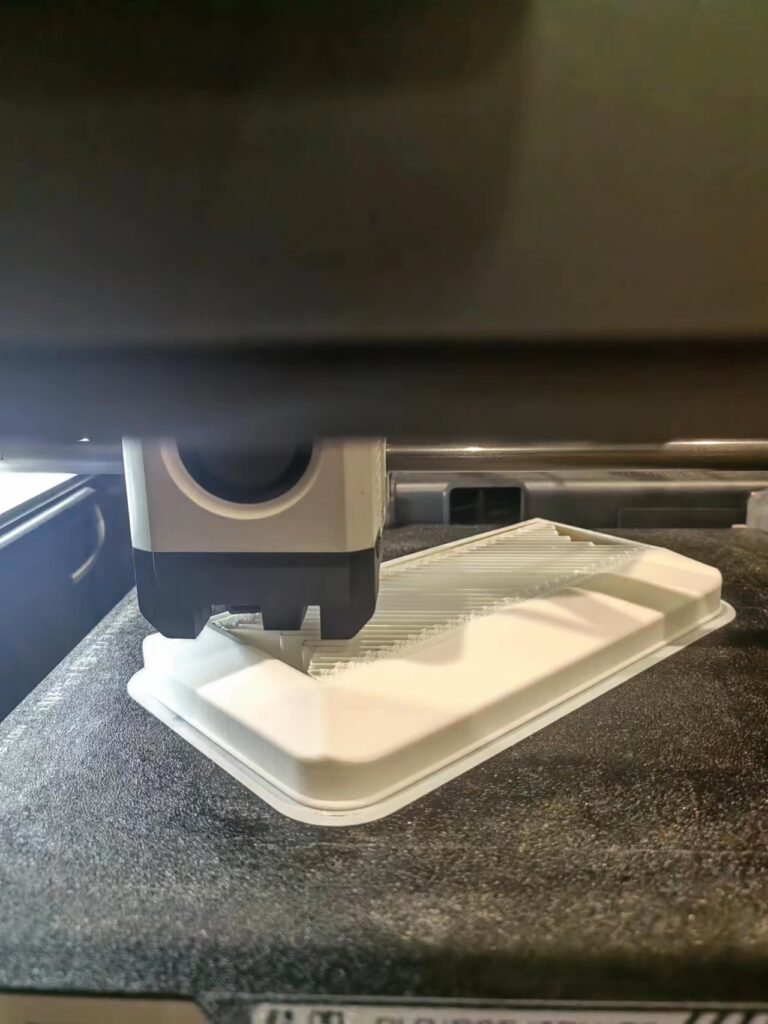

For new mold development project, how to make sure if the new mold size is perfectly fit your product?

Don’t worry about this measurement. Tinspkg would proceed plastic 3D sample for you and test the size, volume before mold set up. You can revise before that to avoid any potential risk of money and time loss.

Plastic sample usually takes 3-7days to complete. Plastic sample would be 1:1 with the same structure as the tin box you need. We shall proceed mold set up exactly according to the approved plastic 3D sample.

Calculating the volume of tin can or jar

Most of our decorative tins are not suitable for liquid storage. For seamless tin cans, we are able to provide exact volume-gram, oz, ml accurately. These seamless tin can is greatly workable for candle, wax, balm and other storage.

From 0.25oz to 16 oz deep seamless tin can, you can always find similar mold available at Tinspkg. Not only slip lid but also screw top mold workable.

In conclusion, before starting your custom tin packaging order, you need to have a accurate idea about the box you need to customize. Get in touch with Tinspkg to learn more about custom metal tin packaging possibilities to make your brand stand out.