Differences between tinplate cans and aluminum cans

People always see and buy products that are packed by metal plate can packaging, while may know less about metal plate material used. Here we shall talk about can produced by the main materials between tin and aluminum.

Tin vs Aluminum Packaging-Which is Better?

Although some people use the tinplate can and alminum can interchangeably, the two types of cans are not the same thing. People use tin cans and aluminum cans for the same purposes. However, the two items are made of different materials and have different characteristics and manufacturing cost.

Cans have been quick-acting storage containers since 1810, when the tinplate can was patented. Aluminum cans were not introduced until 1965. Aluminum and tin cans have many uses, but they are probably best known for preserving and preserving food. Both cans protect food from light and air and are durable and recyclable.

Material difference

Tinplate Can (Tin Can)

Tin is a low-melting-point crystalline metallic element that is ductile at room temperature. Tin is usually extracted from a mineral called cassiterite, which is a compound of tin and oxygen. The basic refining process of tin makes it attractive for manufacturing. Tin does not corrode easily, which is why it can be used in cans. Modern tin cans are actually made of steel coated with a very thin layer of tin to prevent the steel from corroding.

Aluminum

Aluminum is still a metallic element. Unlike tin, which makes up only 0.001% of the Earth’s crust, aluminum is very abundant, or 8.2%. However, aluminum is difficult to refine and is often found in natural compounds, usually potassium aluminate or aluminum oxide.

Over time, different processes have been developed to refine aluminum, and each process has become more and more efficient. Aluminum cans are made from aluminum alloys, which are known for being strong and lightweight.

Tinplate cans are heavier than aluminum cans and have high durability. Tin cans are also highly resistant to corrosion from acidic foods such as tomatoes. However, tin cans are less efficient than aluminum. Recycling aluminum instead of processing new aluminum cans has a higher recycling rate than plastic and glass because the savings are enough to cover the cost of recycling and collecting aluminum cans.

Different characteristics

1. Sealing performance

Tinplate cans have better sealing performance, which can prevent air, moisture and light from entering the can, maintaining the freshness and quality of the product. If you have no request for sealing performance, you can choose decorative tin can packaging. We usually see decorative tin cans applied for cookie, tea, candy, balm and more. Decorative tin cans are more customizable in shapes and sizes. The sealing performance of aluminum cans is slightly inferior, but its inner coating can effectively prevent the intrusion of external factors.

2. Plasticity

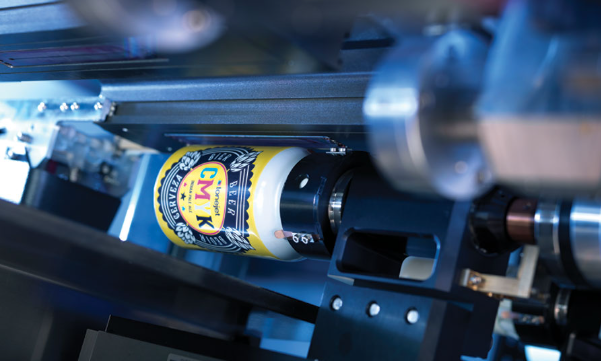

Tinplate cans have good plasticity and can be made into cans of various shape and sizes. Tin can can be made into regular rectangular shape, square shape, round shape, cylinder shape, heart shape, triangle shape, start shape and any other unique shapes. Furthermore, tin can can be applied with any printing effect fully. Aluminum cans are relatively fixed for shape mainly round cylinder can but size is versatilely changable. They are made into shape then printing. Tin can is to set up tinplate printing firstly then made into shape.

3. Anti-ultraviolet ability

The colors and printed patterns of tinplate cans are brighter, longer-lasting, and less likely to fade. This is because tinplate cans have good anti-ultraviolet ability, which can effectively prevent sunlight exposure and oxidation. Aluminum cans need to be coated with an anti-ultraviolet coating on the inside to achieve the same effect.

Different application

Tinplate cans are mainly used for packaging of food like chocolate, biscuit, beverages, cosmetics and other products because they are anti-corrosive and have good sealing properties and plasticity. Aluminum cans are mainly used for packaging of beverages, medicines, cosmetics and other products because they are light, easy to carry and easy to recycle.

Conclusion

In summary, tinplate cans and aluminum cans are different in terms of materials, characteristics and uses. Consumers should choose appropriate packaging containers according to the needs of different products when purchasing.