How to Customize Tin Boxes

The power of first impressions for your brand cannot be overstated. You’ve probably come across ready-to-ship tin boxes, but have you used custom tin boxes? Beyond their aesthetic appeal, durability, and environmental friendliness, the biggest reason businesses choose tin boxes is their ease of customization. Custom tin boxes make your products stand out on the shelf and increase your brand’s visibility.

Are you looking for a metal tin boxes reliable manufacturer for your brand package? Customizing your tin box involves applying personalized designs, graphics, and messages. That’s what we do and the goal is to transform simple tinplate sheets into beautifully functional packaging for your business. We’ll break down the customization process into four steps:

Pre-customization phase

After you and our professional sales communication, we would provide you some basic solutions like to use our existing mould or customize your own size/shape mould and rough budget. All of our tins are customized and no stock for sale.

What shape of tin box you’d like to create for your brand?

Tinspkg have over 11years of metal tin products manufacturing experience, no matter you are looking for regular mold or some personalized irregular mold we all can realize. We specialize in regular round tins(cylinder), square cans, rectangular tin box, oval tins, heart-shaped tins, as well as irregular shapes like triangle-shaped metal tins, tree-shaped metal tins, book-shaped tin cans, bus-shaped tins, truck-shaped tins, another custom special shape etc. Special shapes may be more expensive due to the need for extra tooling and specialized molds.

What Works With Tin Containers?

Except for shapes, we need to learn your tins application would be helpful to recommend best structures of fitting lids and closing mechanisms.

Our premium metal tin products are made by high quality tinplate and they are pretty good for:

For regular food tins-biscuit, tea, coffee, gummie, mints candy, chocolate, sweets, popcorn, spice, snacks, wine etc

For decorative & gift tins-candle tins, pencil tin case, ice buckets, cosmetic tins, tin coin banks, tin jewelry boxes, watch tins, perfume tins, CD tin boxes, coin bank, metal tin sign, etc

For festive & holiday tins-Christmas tin boxes, wedding tin boxes, Easter, Thanksgiving, etc

The raw materials commonly used for custom tin cans are tinplate smooth iron, tinplate ground iron or galvanized iron. All our tin containers are made of high-quality tin plates sourced from reputable suppliers. If you’re into food or cosmetic products, you can be confident that our tin raw materials fulfill the standards for food grade and environmental preservation.

Customization Phase

Where your tin box design begins is to take shape and size. You and Tinspkg would work closely to bring your design idea to life. You can share any of your idea to modify with our professional design team.

1. 3D mockup

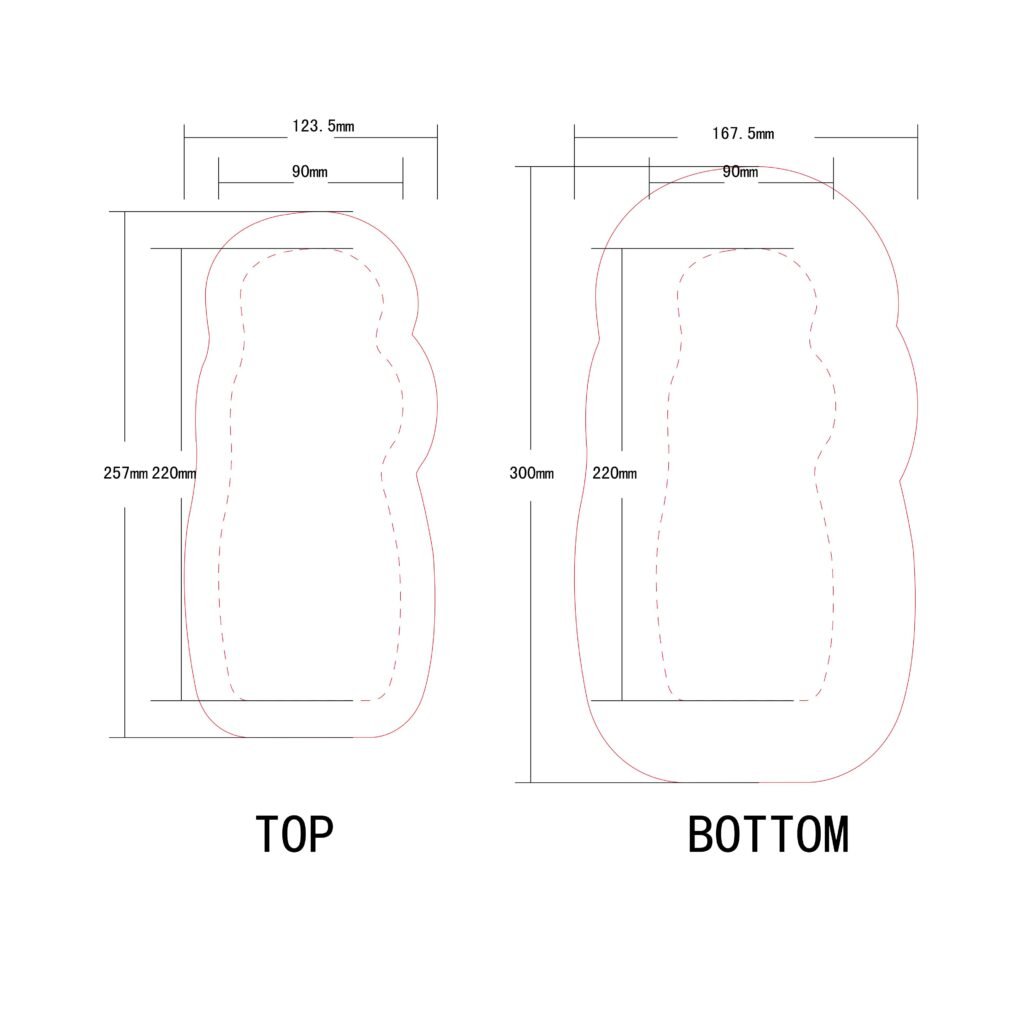

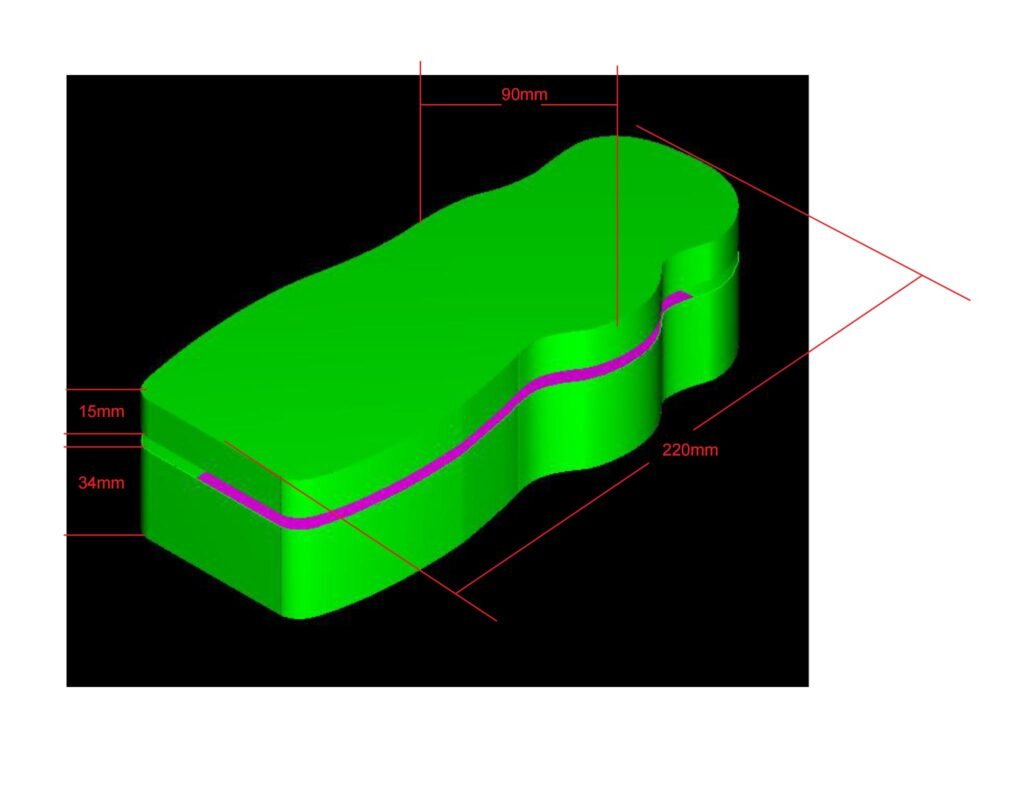

Based on your hand drawing(sktch) with size request, our design department would make a 3D mockup to confirm the strucure and function. Before investing a lot to tooling setup and time, Tinspkg would help client to make plastic physical sample to test the size and structures for approval. That would take 3-7 days to finish.

2. Set up Mould

After the 3D plastic sample is confirmed, Tinspkg will create custom mold sizes tailored to your specific product dimensions. Generally, custom mould lead time 15-20 days depending on the metal tin products structures and size.

Internal Dimensions: Measure your product accurately to ensure it fits snugly within the tin. This helps to prevent movement and damage during transportation. In your calculations, give allowances for additional materials, like liners, dividers, or protective wraps, that will be included inside the tin.

External Dimensions: External sizing should take into account storage, shelf space, and shipping logistics. Tins that stack well in shipping cartons minimize wasted space and shipping costs.

3. Structures of fitting lids and closing mechanisms

After selecting the shape and volume or size of your custom tins, you may need to consider the closing mechanism you prefer to use.Specialty closures can draw extra attention to your product. Tinspkg offers numerous options for tin boxes with lids, including hinged lids, sliding lids, screw caps, see-through lids, and slipcovers. The choice depends on the product and the aesthetic you’re aiming for.

Window

Slip Lid

Screw Top

Hinge Lid

Slide

If any of above can’t meet your needs,we also provide unique specialty closures like decorative metal snap lids, which add a premium, collectible touch. On request, all lids can be equipped with an EPE liner to help seal your tins more tightly and keep your product fresh.

4. custom embossing & debossing

Embossed and Debossed designs are popular finishing techniques for packaging and printed items to create raised or recessed designs on the surface of tin cans.

embossing mold

Firstly, these embossing or debossing techniques can give your metal tins a 3D tactile feel and appearance to show a sense of sophistication and luxury

Secondly, they create a tactile experience for customers, making the product more memorable and appealing.

Furthermore, embossing can be combined with full-color printing for an even more striking effect that catches the light and help the customer make informed purchasing decisions

Further Reading: How to Emboss/debossing onto Metal box?

debossing logo and pattern

ebmossing for logo and pattern

5. Finish options

A great finish to add your tin box design’s visual appeal and depth. Beyond aesthetics, finishes also provide a protective layer against corrosion. Standard finishes used by Tinspkg include:

These finishes can also be combined to create unique effects, such as a matte over gloss finish.

About Tin Materials

All our tin containers are made of high-quality tin plates sourced. You can be confident that our tin raw materials fulfill the standards for food grade and environmental preservation.

Pattern design

Customers send us their artwork and we shall display it with the dieline to make sure the logo, texture and others are properly shown. And designer would make 3D rendering for approval.

Or Tinspkg graphic designers help to develop the visual elements such as the logo, brand color schemes, images, and typography, so you can share your love.

How To Print On Metal Packaging

Full-color printing

CMYK(cyan, magenta, yellow, black) four-color dot overlay to replicate the required color, belonging to the principle of the subtractive color method, which is the most conventional printing process, color brightness is higher, less saturated, but prone to color deviation.

Spot colour printing

Spot color printing uses a single color ink other than yellow, magenta, cyan, or black to reproduce the color of the original. It belongs to the principle of color mixing, by blending a single ink color to present the desired effect. Spot-color printing is fuller in color, with fewer errors, but at a higher cost.

Printing with metallic

Printing with metallic (foil stamping)shows the original tinplate metallic luster effect

In addition, there are relief printing, silk-screen printing, flexographic printing, spraying, electroplating, water transfer printing and other processes, according to different packaging requirements to choose the appropriate printing process.

Production

At Tinspkg, we have advanced technology and skilled craftsmanship to produce high-quality tin boxes. For large quantity orders over 50k pcs, we would use our fully automated lines to ensure consistency throughout production with lower cost.

Tinplate sheet cutting: generally one piece of printed tinplate is approx 1085*960mm, workers shall accurately cut them into small pieces for stamping process. The cut and stamped pieces are assembled into their final shape using both machine and manual techniques. After clean and QC process, all assembled tins are packaged and ready for delivery.

Looking to Begin Your Tin Box Project?

There are many things to consider when proceed Tins customization. No matter you are the first time to personalize your brand tins or not, we can also provide excellent and fast professional service to save your precious time and cost. Our design department wold help to make your design come true and create your product. If you have made up your mind and are looking for a partner to start your custom Tins journey, Tinspkg can help. Let’s create something great together!

Existing tooling guidelines and time

| Pre-customization phase | shape, structure, size and application | 10-20days |

| existing tooling | ||

| customization phase | Printing artwork design (with existing mold dieline) | |

| Printing artwork design (with existing mold decline) | ||

| 3D rendering | ||

| Printing effect confirmation | ||

| Physcial proof make |

Custom tooling guidelines and time

| Pre-customization phase | prefer to customize new personalized tooling | 20-30days |

| prefer to customize new personized tooling | ||

| customization phase | mold 3D mockup and 3D rendering | |

| Physical proof make | ||

| Printing artwork design | ||

| mold set up (include embossing or debossing mold) | ||

| Printing effect confirmation | ||

| Physcial proof make |