What are Embossing and Debossing in Packaging

Embossed and Debossed designs are popular finishing techniques for packaging and printed items to create raised or recessed designs on the surface of tin cans.

Why do people prefer to choose the tins with embossed or debossed decoration?

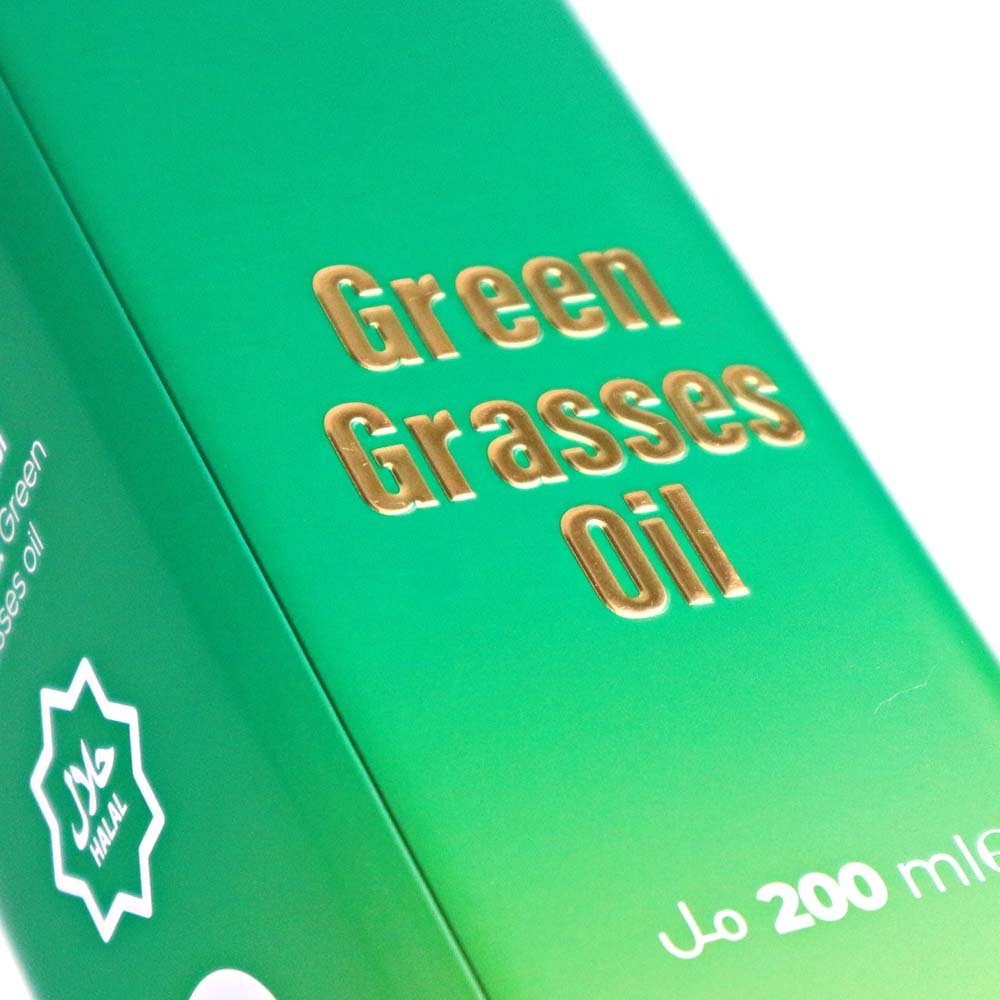

Firstly, these embossing or debossing techniques can give your metal tins a 3D tactile feel and appearance to show a sense of sophistication and luxury

Secondly, they create a tactile experience for customers, making the product more memorable and appealing.

Furthermore, embossing can be combined with full-color printing for an even more striking effect that catches the light and help the customer make informed purchasing decisions.

How to Emboss onto Metal Box

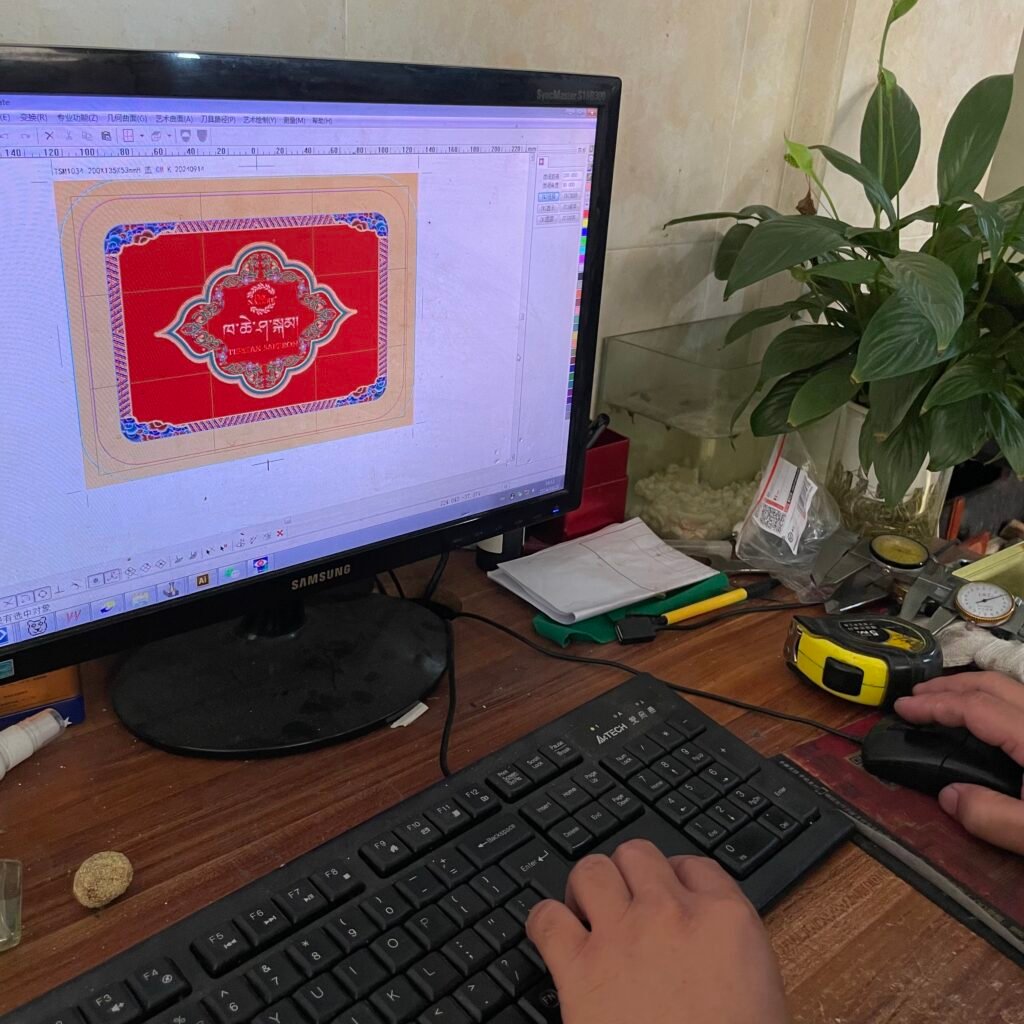

The first step is to check the embossed or debossed artwork (logo and pattern), then recommend the best solution and 3D look how it would show.

Make sure the logo or pattern embossing/debossing is 2-3mm distance to the edge

It’s vital that Engraving depth would affect metal tin production quality. If deep engraving is sharp, the metal tinplate would be broken. Tinspkg’s suggestion for word embossing or debossing is generally 2mm; for other patterns 3D engraving is 5-10mm.

If your artwork shows logo or words are too small, we would not recommend embossing or debossing for it is hard to position. How to define if your logo or words are small or not, we shall suggest a size not less than 1mm.

The above important regulations make sure the following custom tins production successfully.

Before proceeding with custom embossed tin box production, we need to proceed with customized embossing mold first.

The designer make 3D mockups for approval and embossing mold customization by fully automatic high-precision engraving machine to make our emboss tool accurately engraved that is important to make sure the following embossed tin production quality.

When embossing process done during tin box production?

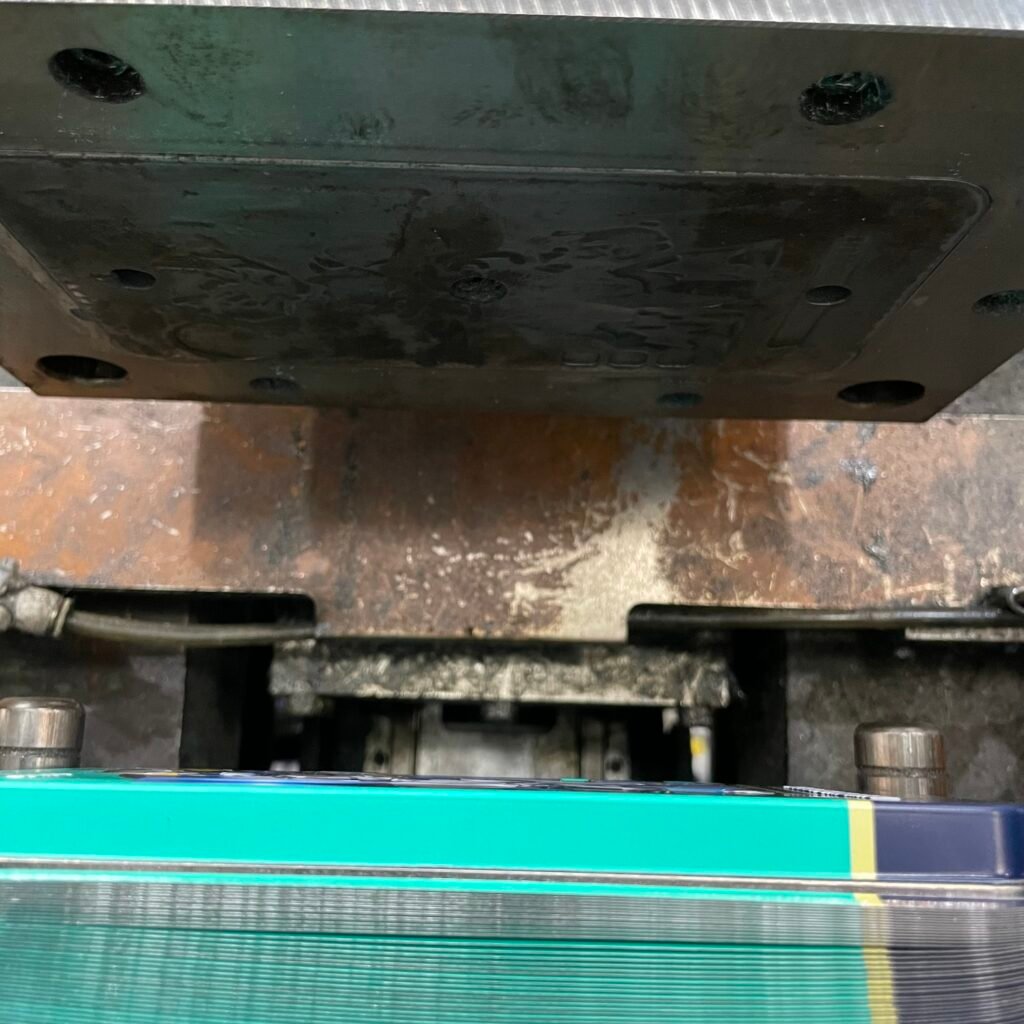

How do we make sure the embossed part will not be stamped again on the second or following stamping production?

They are good questions. Please check the below pictures for a better understanding.

Although plain metallic embossed tins already look like a masterpiece, you’ll also be able to take it a step further by combining this technique with a full-color print. Generally, it is done on the first stamping machine to make sure logo and pattern on tinplate sheet are accurately embossed and matched.

You can refer to below pattern embossed tin box for mobile phone battery. It’s made by high-quality 0.23mm tinplate with white base CMYK & Pantone color & matte glossy finish printing, inside silver varnish. We make the other following stamping mold upper part engraved empty to make sure the embossed logo or pattern not affected.

Tinspkg is not only professional on the top lid or bottom embossing but also for tin box body side custom embossing.

They share the same tooling setup and embossing procedure as the top cover but are only different during shaping.

For the cylinder tin box, it is easy to proceed and you only need to display it in different directions and avoid the embossed part being affected.

In terms of rectangular or square-shaped tin box-making custom embossing on the body, we have to make the shaping mold partially engraved to avoid logo or pattern stamped.

What’s the lead time for a new customized embossing mold?

Embossing proportion and difficulty are the main factors. Generally, it takes 5-10 days to prepare metal tin mold material, embossing artwork designing to engraving. The Tinspkg team has strict procedures from the beginning to the end. Each department works closely to show sincere confidence to meet the client’s perfect tin packaging demand.

What’s the leather effect on embossing and debossing on a metal tin box?

There is a special embossing/debossing display we call the leather effect. It requests high density and high precision for the mold. We have well studied the nature of leather and achieved the leather effect techniques on tin boxes. It’s a breakthrough to help clients meet their high-end customer’s needs.

Would be very expensive to make a personalized embossed tin container?

Comparing regular custom-printed tins with embossed custom-printed tins, yes unit cost would increase as production difficulty would increase and procedure more but not much. The embossing process would increase the risk of scratches on the surface of the tin box and we need to invest more printing for spares. In addition, the main investment for customers is the embossing mold.

Embossing mold cost would be mainly in terms of embossing area and difficulty. Please send us your rough design and we can quote you soon. Let embossed tin packaging boxes leave a mark on your customers with attention to detail customization. These boxes ensure safe product delivery to your customers while impressing them with unique designs. Get in touch with us to explore a range of tin packaging boxes!

What’s the MOQ to make embossed tins with personalized artwork?

Minimum quantity for embossing together with printing customization shall be 3000pcs and we would recommend client to do 5000pcs to get a competitive price.

Here are some of the reasons why choose Tinspkg for custom metal tin packaging solutions;

- Premium materials ensure durability and longevity.

- Customization options for a personalized touch.

- Competitive pricing for bulk orders.

- Fast and reliable quality assurance

- Dedicated customer support to assist you at every step.

Embossing or debossing decorations are widely used for any shape of metal tin box. No matter you are looking for metal tins with customization on printing and logo embossing or plain silver tin only, all we can meet your needs fast.

Let’s enjoy your tin can customization journey now!