Why tinplate is suitable for making tin box?

Tinplate has been widely used as a packaging materials or processed to be other tinplate items like tinplate coaster, tinplate sign trays, tinplate toy and more.

Here let’s learn more about why tinplate is suitable for making tin box. Tinplate have below unique combination of properties, making it idea for packaging and storage.

The Tinplate Can Advantage

Corrosion Resistance

Tinplate is made by coating thin steel sheets with a layer of tin, which provides excellent resistance to rust and corrosion. This makes it perfect for storing food, beverages, and other moisture sensitive products.

Strength and Durability

The steel base provides structural strength, allowing tin boxes to withstand impacts, stacking, and rough handling. Tinplate containers are rigid and protect contents from physical damage.

Formability and Workability

Tinplate is highly malleable, allowing it to be easily shaped, stamped and formed into various box designs(round, square, star, heart, custom shapes). There are two types of assembly for tins; one is seamlessly welded or soldered for airtight and leak-proof; another is crimped tins by stamping machine. Welded tins you can obviously see there is a line but crimped tins no.

Feature | Welded tins | Decorative tins |

|---|---|---|

Seal Strength | Airtight, leak-proof | May not always be fully sealed, not working for liquid |

Customization | Limited(focus on function) | High(shapes, sizes, printing, embossing, finishes) |

Cost | Lower(mass-produced) | Higher(design-driven) |

Durability | High(impact-resistant) | Moderate(prioritizes looks) |

Seam Type | Welded(electric resistance welding for airtightness | Often crimped, folded or soldered for visual appeal |

Lid Attachment | Tight-sealing lids(snap-on, screw top) | Hinged lids, magnetic closures or lift-off tops, screw tops, window lid, click clack lid, Child resistant lid, lid with decorative handles, etc |

Application |

|

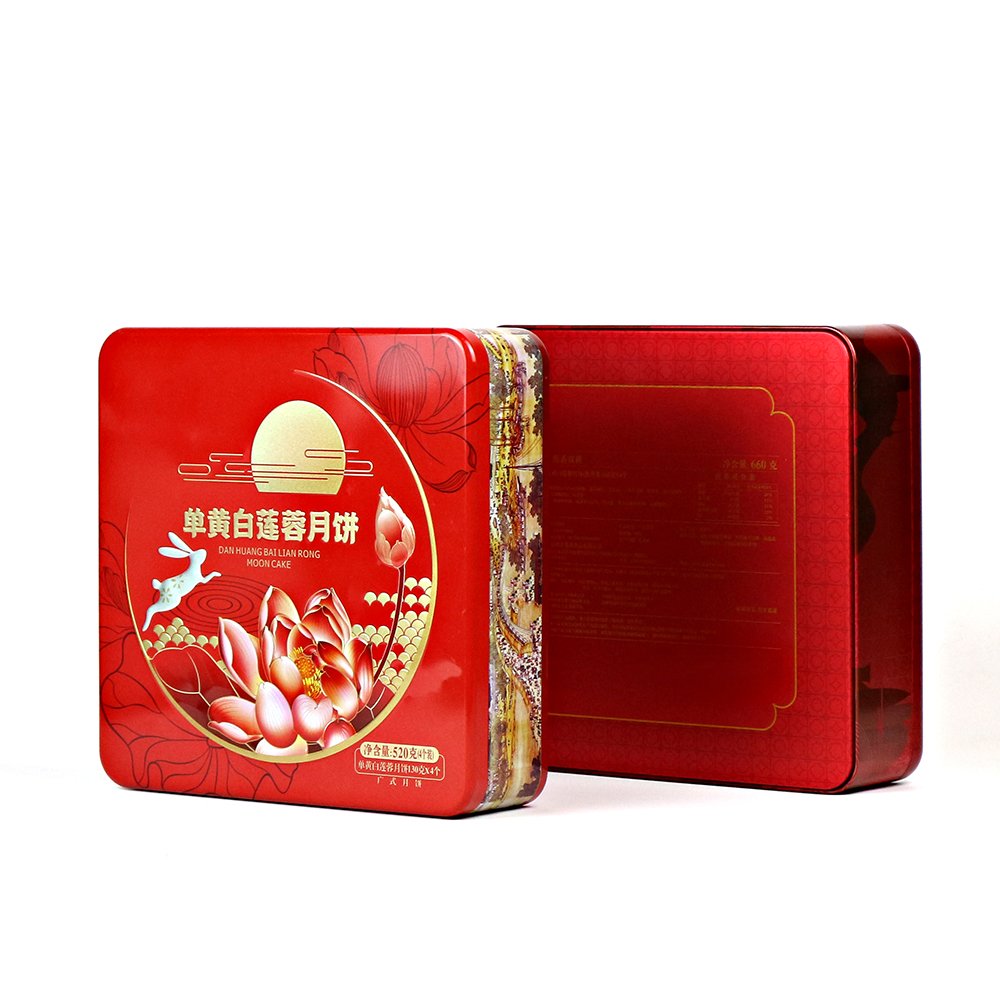

Excellent Printability and Aesthetics

The smooth tin surface allows for high-quality printings, embossing and decorative finishes. Brands use tin boxes for attractive packaging due to their glossy, metallic appearance.

Food Safety and Non-Toxicity

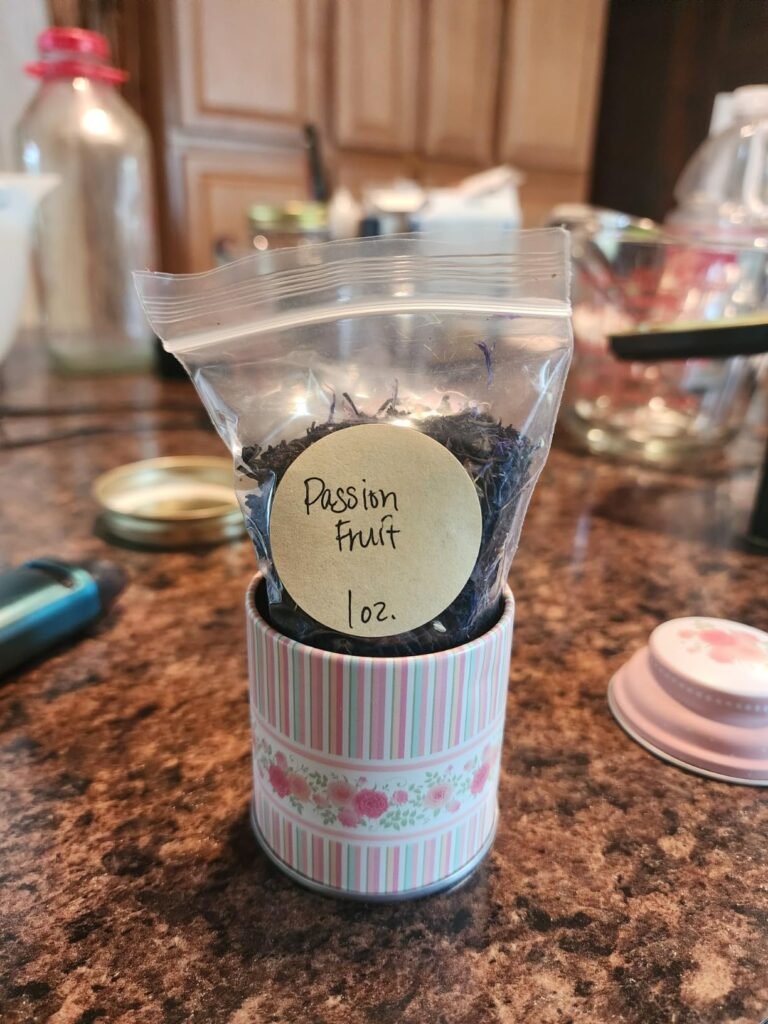

Tin is non-toxic and FDA-approved for food contact, making it safe for storing edible goods( tea, cookie, candies). It doesn’t react with food, preserving flavor and freshness

Recyclability and Sustainability

Tinplate is 100% recyclable without losing quality, making it an eco-friendly choice. Many industries prefer it for sustainable packaging solutions.

Barrier Protection

Tin coating blocks oxygen, light, and moisture, extending shelf life for perishable items(e.g., coffee, spices, medicines)

Heat Resistance

Tinplate can withstand high temperatures, making it suitable for sterilized food packaging(e.g., canned vegetables, seafood)

How to choose the correct tin box for your products welded tins or decorative tins?

Before ordering tin box, you need to know your products filled in tins. Choose weded tins for storage, sealing and industrial use. If you products belong to vegetables, fish, drinks, oil which need high airtighness feature tin container, you would definitely choose welded tins.

Opt for decorative tins for marketing, gifting, and visual appeal. You can create any adorable and unique shapes tin box like bear shape, house shape, tree shape, dog shape or others to make your brand appealing.

How to Customize Tin Boxes

How to make full printing customization for your tin box?

High quality printing is one of the key concern on packaging. Printing helps your brand stand out and keep your product long shelf time. The main printing method is offset printing process that is directly done on tinplate sheet before forming, you can achieve any printing you want glossy finish, matte finish, glossy and matte finish together, metallic printing

How to make custom printed logo or pattern embossed or debossed on tin box?

Embossing or debossing effect always show people more impressively. To make logo or pattern embossing, the first step is to make embossing tooling according to your logo and pattern artwork, then getting printed tinplate sheet stamped. You would get a beautiful and accurate embossed tin box.

Further Reading:

In conclusion

Tinplate’s durability, corrosion resistance, formability, and aesthetic appeal make it the top choice for manufacturing tin boxes across industries. Its ability to protect contents while being eco-friendly ensures its continued popularity in packaging. Tinplate is one of the most important sustainable packaging material with versatility.