One-stop customized service

Our customers are always at the heart of our decision-making. From the beginning to the present, our business has been committed to providing comprehensive metal packaging solutions, offering value-added services to our clients, and co-developing products with them, including decorative closures and custom packaging designs.

We Provide All options for Custom Tins

As an advanced tin cans factory, Tinspkg can provide 100% customization for your tins packaging.

Tinspkg have over 2500+ molds of various shapes and sizes tins. You can choose existing toolings to make your customized tin packaging (designs, logos, patterns, colors and embossing) that is efficient and affordable. If our molds are unable to meet your requirements, we can create a custom shape and size mold for you. Bring your product vision to life with attention-grabbing details, shapes, graphics and finishes personalized to your brand. Quick 3D product preview, 3D plastic sample for size and structure approval, mold development, printed sampling making, one stop service to achieve your custom premium tin packaging. Let’s start from here to easily customize your sustainable, food grade, durable and 100% recyclable tin packaging.

Tinspkg produce custom tin cans for food and non-food field. We provide flexible customization services for metal tin cans / tin box with a wide range of lid types to meet both functional needs and branding requirements. Whether you need food-grade packaging, cosmetic tins, or specialty gift boxes, our mold R&D team can design and create new packaging solutions for you.

lid Edge curved out

lid Edge Curved in

click clack lid

plug-in lid

clip lid

Neck-in lid (double layer)

Full window lid

Latch cover

Double lid with knob

Easy peel off foil lid

Pull-tab aluminum lid

Screw top with rubber seal

Screw top with plastic cap

Slot lid (bank tin)

Plastic cap

Stackable lid

Lid with plastic handle

Lid with lock

Lid with metal handle

spout lid

Stackable lid

Tinspkg offer a variety of metal packaging printing and finish solutions to create a distinctive and custom premium look for your brand.

CMYK offset Printing

Spot color Printing

Glossy Finish (shiny)

Matte Finish

Crackle finish

full Metallic Printing

gradient Colors

Glossy with matte finish

Metallic Gold Printing

Laser coated Printing

.jpg)

Partial metallic printing

Clear lacquer (transparent)

Gold lacquer

As a metal tin packaging manufacturer, we provide embossing & debossing customization service with versatile options:

Custom 3D embossing

Custom debossing

Custom Single-level embossing

Custom Blind embossing

Custom registered embossing

Custom full surface embossing

Tinspkg offer a range of custom inserts for tin box packaging. Inserts can be made from different materials depending on the product’s needs.

Paper/cardboard insert

Eco-friendly and low cost; can be folded, slotted or die-cut to hold products.

Foam insert (EVA, EE, PU foam)

Soft cushioning, die-cut to fit product shape. Mostly available in black, white, or some colored foams

Metal or Tinplate insert

Inner tinplate divider or tray which is easy to be 100% recycled without extra process.

Plastic insert (PVC, PET, PP, PS)

Transparent or opaque molded trays that gives clean, premium presentation.

There are versatile solutions for custom metal tin packaging, including not only printing, embossing, window features but also decorative add-on or accessories like clasp, beaded handle, plastic handle with latch lock, ball handle, metal clip lock etc. These make bespoke tin packaging absolutely adorable for storage and gift giving, perfect for carrying lunches, snacks, small toys, treasures, storing small accessories, makeup and stationery. Check below to find your customization preference

1. Beaded carry handle

Oval tote tin with beaded handle

Handle clasp and hinge

Beaded handle design great for carrying on-the-go items, snacks or toyscustomization preference

Beaded handle color customization

Other shape and size tins can be customized with beaded handle as well

2. Metal latch lock

Tins with an easy-to-use latch lock and an air-tight plastic seal is perfect storage solution for tea, coffee or dry products.

Versatility of reusable container with latch

Latch lock can be customized to match round or square tin container

Latch lock color can be silver or gold to meet your demand

3. Plastic lid with latch lock

Tins with an easy-to-use latch lock and an air-tight plastic seal is perfect storage solution for tea, coffee or Metal latch lock tin with plastic lid comes with an easy-to use latch and an air-tight rubber seal

Plastic lid shape, size and color can be customized to match your brand. It can be clear window lid as well.

4. Tin box with plastic handle and clasp

Tin box with plastic handle and clasp is widely regarded as lunch tin box or carry storage box.

Bespoke plastic handle color and size to match different tin box

Silver metal clasp popular choice

5. Ball handle

Ball handle is a decoration widely applied for round tin containers. It makes tin box lovely and attractive.

Ball handle can be customized into different material metal or plastic.

Ball handle color can be customized as well

6. Metal clip lock

Metal clip lock used for square or rectangular tin box

High quality metal click lock made by stainless steel

Size and thickness customized

Custom Tin Cans For Your Business

Our custom packaging services cater to a wide range of products. Whether you’re looking for personalized aluminum tin cans, container, canister or jars, we’ve got you covered. All our packaging materials are crafted from sustainable and recyclable materials. You have the option to personalize it with custom-printed designs and add-on. Alternatively, we can assist you in creating a brand-new and unique custom packaging from the beginning of mold development.

TINSPKG is a one-stop custom metal tin product supplier. We have produced thousands of types of tin container in different colors and capacities. We can provide customers with the best price and quality tin container.

- Area: 6000 Square Meters

- R&D engineers: 3 Staffs

- Tin Molds: 3000+ Sets

- Production Worker: 60+ Staffs

- QC Team: 7 Staffs

- Production Capacity: 2,000,000 PCS Per Month

- Machines:

- 110 Stamping Machines

- 5 Automatic Cutting Machines

- 6 Automatic Production Line

- 3 Packing Line

Please note: The right lists are only part of our Tin container. For more detailed types and specifications, please check our catalog or contact us.

Tins Design

Get Your Needs And Give Pre-Advice

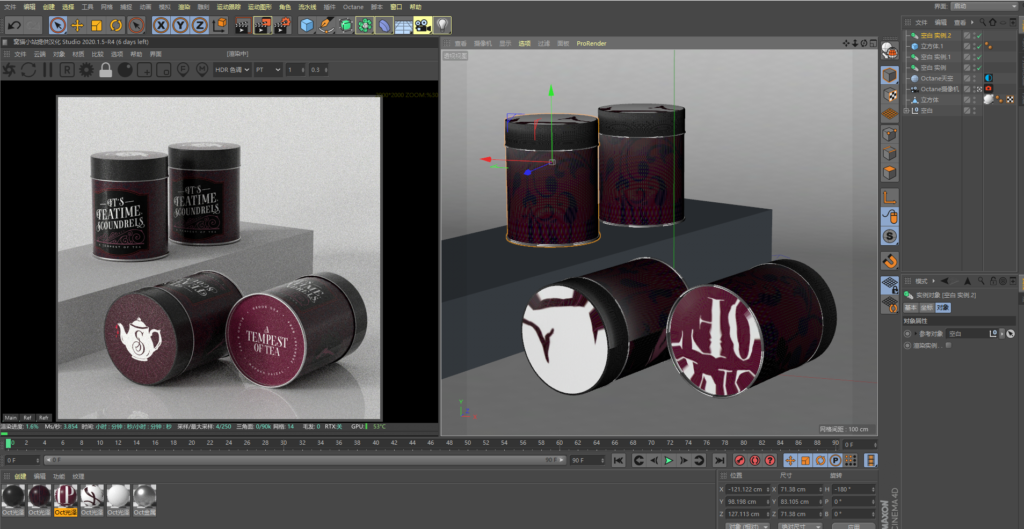

We engage in dialogue with our clients to understand their specific customization requirements. We then conduct thorough market research and provide well-informed, scientific recommendations. Following this, we initiate the design process by creating 3D renderings of the proposed products.

We draft technical specifications and other relevant parameters based on the client’s detailed needs. Once clients have finalized the custom samples, we proceed with physical proofing to bring their vision to life.

Logo and print

Decoration And Labelling For Your Packaging Business

A quick and easy way to create custom packaging is to add adhesive labels to your existing containers. However, there are many more ways to make your packaging stand out. At TinsPkg, we offer a variety of customization methods that allow you to add a unique touch to your brand’s packaging materials.

Production and Manufacturing

Wide Range Of containers To Choose

We manage your manufacturing comprehensively to ensure efficient production, stringent quality control, and strategic sourcing. This approach allows us to offer you competitive pricing, which in turn helps to reduce costs.

Packaging and shipping

Safe and On-time delivery is guaranteed

On-time delivery is guaranteed—quantitative stock is kept ready, and custom models are dispatched after the design scheme is confirmed. Stock plain tins 7-10 days for delivery. Simple color product production time shall be 10-20 days like black/gold/silver colors. Others with printing customization shall be 30-35 days.

The Process of Custom Tins

1. Provide your Tin Packaging Requirements

Before the customization of your metal tin products with Tinspkg, please kindly provide some essential informations below in order to provide our valuable and effecient feedback for you.

We shall provide a solution based on above information:

Recommend our similar existing mold for you to choose and customize

Except #1 solution, we can customize new mold for you as per your special requirement

If this is your first time to customize metal tin packaging and no much experience on size or shapes, please contact our professional team and we shall provide you one-stop and workable solutions

2. Make the effect drawing for your Project

Based on existing available mold, for custom project, we shall provide below suggestion and solutions:

- we would provide die line of tin box to customer in AI or PDF format. Client’s designer finish artwork and put them into die line and shared to us.

- We shall double check the artwork if words , pattern are correctly positioned.

- After that, we would check with client to confirm the printing effect -if need white base or partial metallic , full metallic printing, any spot color, glossy or matte finish request and suggestions

- Before proof, we can provide 3D mock up with artwork for quick check and approval

Above is based on existing available mold. If you’d like to customize a new mold, we shall provide below suggestions and solutions:

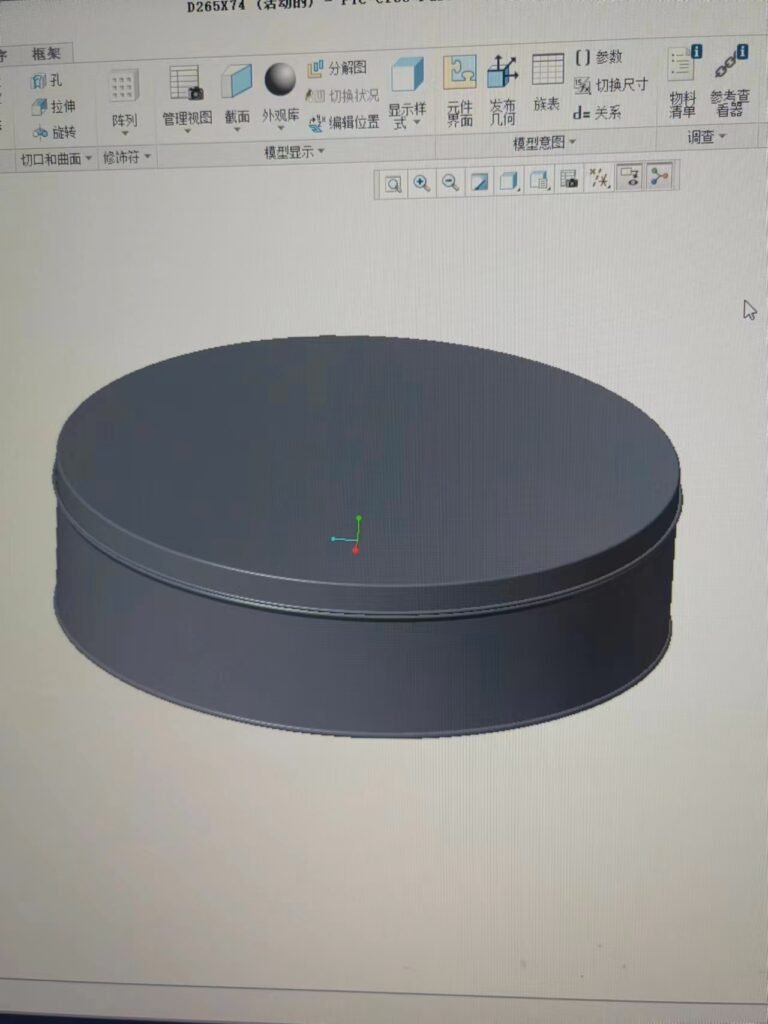

- Making 3D mock up as per size specification or your product information and structure details for confirmation

- Making 3D mock up with client’s artwork for you to have a clear presentation

- After above approval, we would proceed plastic proof. Gerenerally it takes 3-7days to complete

- Once plastic proof ready , we shall ship to you. And you can test size and check the structure

- If plastic proof confirmed, we would proceed mold customization. It would takes about 15-25days which mainly depends on the size and structure of tin box

3. Raw materials for manufacturing tin cans

The raw materials used for custom tinplate cans are usually tinplate, sandy tinplate, galvanized iron. Tin plate and sandy tin plate are with tin layer that is non-toxic and tasteless, with a bright surface. They are meeting food grade, eco-friendly and recyclable requirements which are perfect for food and liquid storage.

A tin layer on the surface of tinplate cans, which can effectively prevent corrosion and protect the quality of food.

Good quality tinplate materials play an important role on the following printing and production process.

- Tinplate material: premium tinplate, high purity aluminum plate

- Tin plate thickness: 0.21, 0.23mm(regular), 0.25mm, 0.28mm, 0.3mm

- Aluminum plate thickness: 0.28mm(regular)

4. Custom product Sample

To make custom printed tin product samples take 7-12days generally, and we need to proceed custom tinplate printing first then stamping into shapes and assembly. After sample ready, we would provide pictures from different side for you to check. Then ship out to your company by express shipping.

If you have any special request for custom sample, we would check all possibilities to meet your demand. In addition, Tinspkg can promise the same quality standard for both sample and bulk cargo.

After sample approval and order placed, we shall proceed mass production as per following procedures:

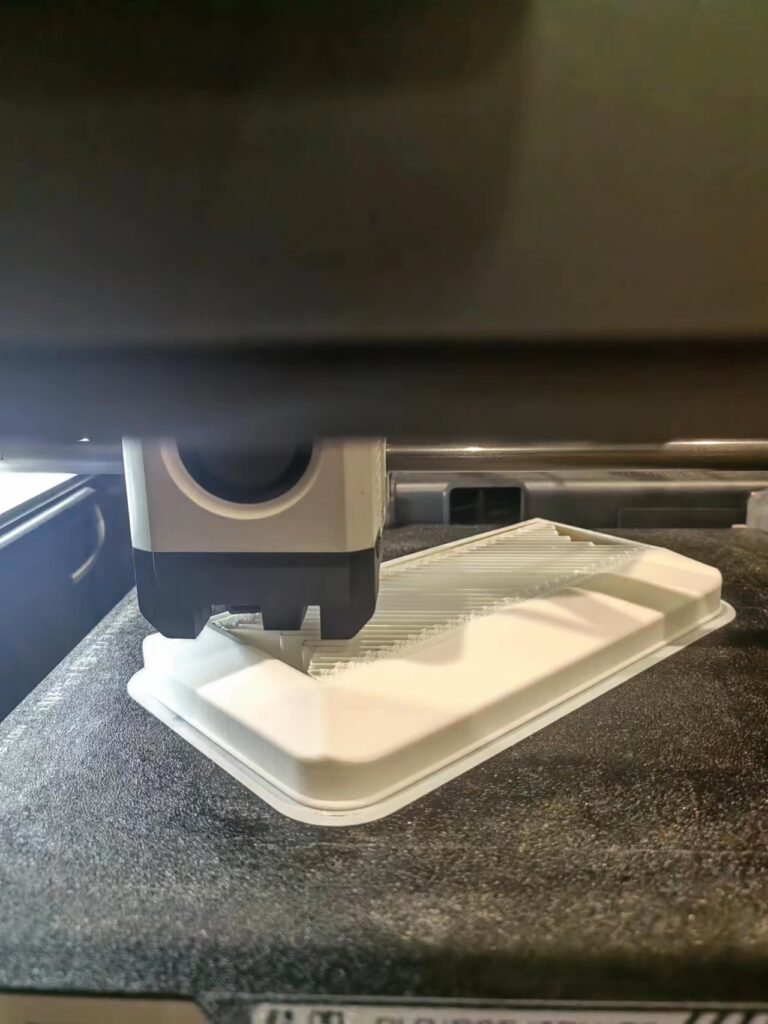

- Firstly Print tinplate sheet with customer’s printing artwork and take the proof for color check

- Cutting tinplate into pieces

- Fix, modify and test mold

- Shaping by stamping machines and assemble

5. Printing Tins

After custom tin sample approval and place order, we shall proceed printing tinplate for order.

Printing tinplate sheet MOQ1500 pieces( tinplate sheet size varies but basically around 960*1080mm).

For small quantity orders, we need to set up different orders together on the same template to print in order to cut down client’s cost

Most tin can supplier use two-color printing machines and unable for finish CMYK process at same time which may cause some color difference and tin plate material loss. Tinspkg use Fuji 4-color printing marchines and one line we can finish all CMYK colors to make sure printing quality.

After color printing process finished, there is an essential step- coating that is greatly helpful for ink adhesion and visual quality. Good quality printing attract more attention for your brand.

Tinplate can be coated differently as per drawings; partly or completely; matte or glossy

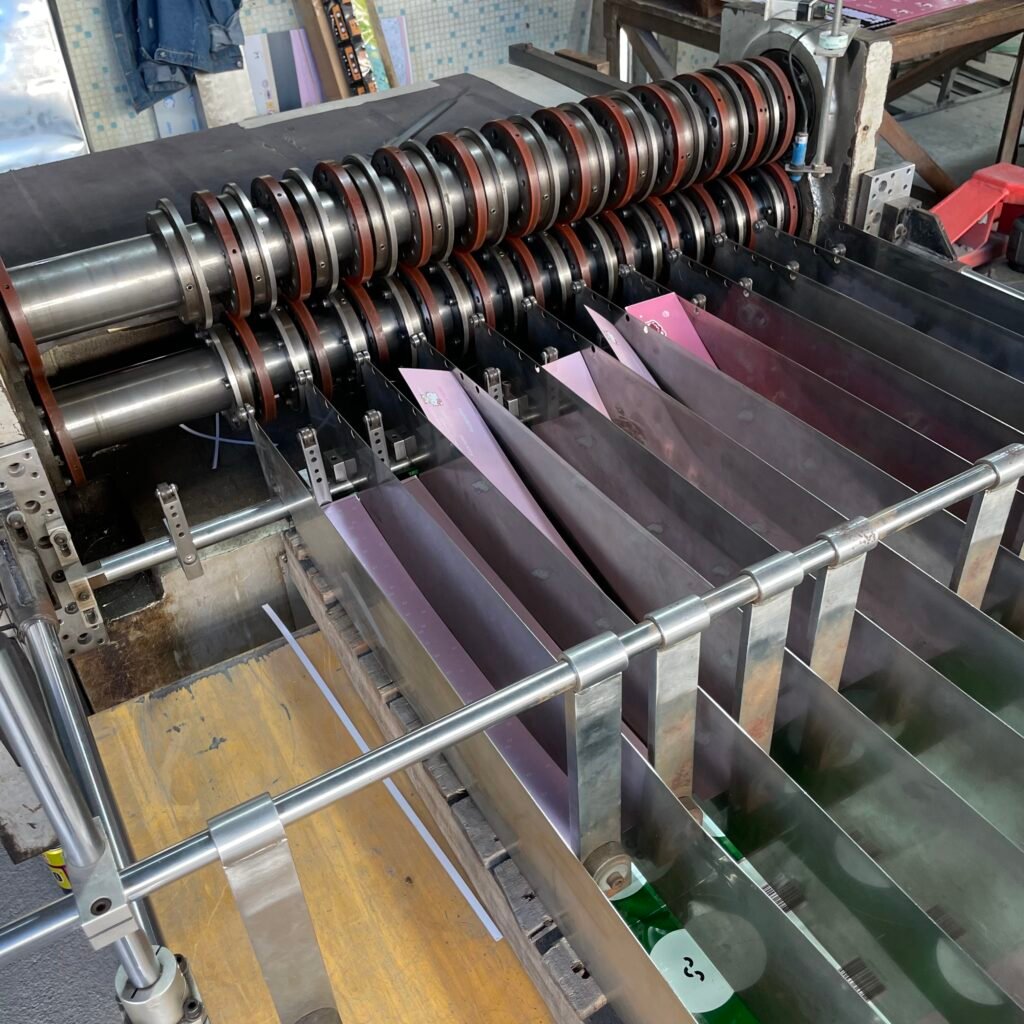

6. Cutting Material

Before printed tinplate sheets cutting, QC person need to check materials surface correct.

Cutting process, we need to cut tinplate into correct size and without scratches to make sure the following production go smoothly

Shearing machines cut large-sized tinplate sheets into small sizes. A tin box is constructed by tinplate lid, tinplate body or tinplate bottom. If there are some errors in the size of tin sheet, it would affect tin can size and artwork position and lid tightness etc. Therefore, cutting correctly is the basis of tin can production.

The thickness of metal tin plate should be less than 0.3mm cutted by shearing machine, or it would affect cutting quality and cause shearing machine damage. Tin plate would have irregular burrs that would affect production as well.

Tinspkg use a fully automatic shearing machine to complet this process and an engineer keep an eye on the shearing machine status.

7. Mass production

One tin box completed requests many different processing molds. Therefore, fixing and modify each stamping machines with every mold and test is very important. These make sure good quality tin box with correct size, embossing accurateness, proper tightness, screw lid works, no scratches and no quality issues.

8. Quality control

Quality represents everything of the company. To find a reliable manufacturer, you should know something about tin production quality control.

From the beginning of tinplate printing to cutting and mass production, every step we have rich experienced staff to check and control.

Quality Control

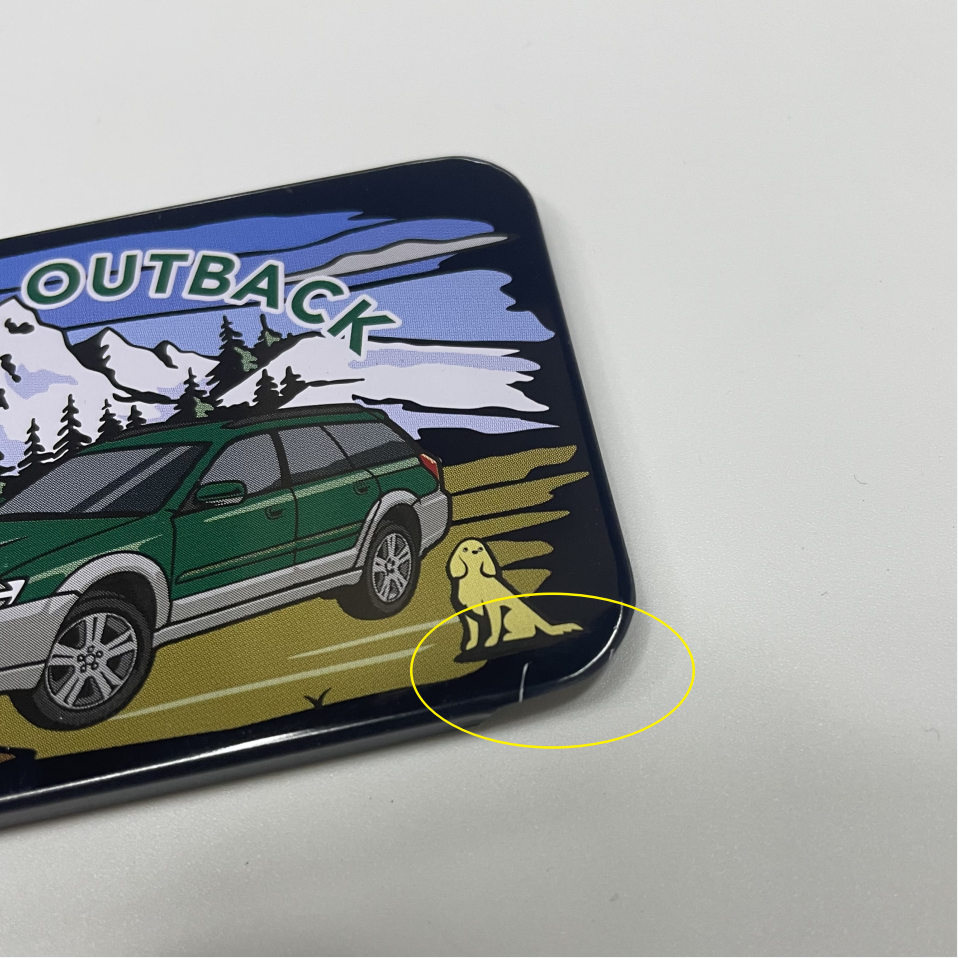

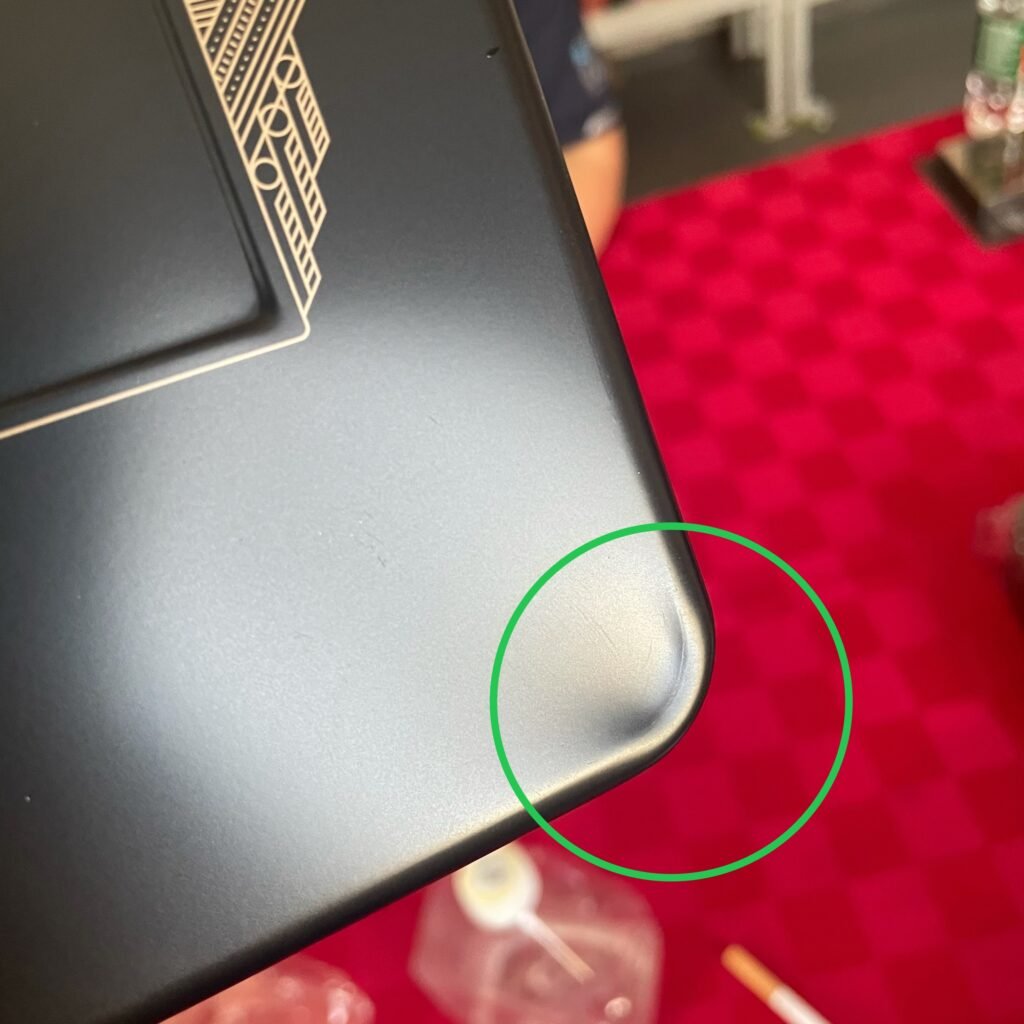

We must focus on and avoid below main quality issues happened during production:

Scratch

Deformation

Dirty Mark

Embossing Deviation

Poor Painting

Rust

8. Assembly and packing

Corret assembly and packing is the last but important process.

Regarding to assembly job with accessories, there are two conditions:

- Accessories purchased and assembled by Tinspkg

- Accessories supplied by clients and assembled by Tinspkg

we have strict packing process manual to show every details how and how many accessories filled into tin box and in which direction displayed in tins,etc.

Furthermore, packing is greatly vital as it would affect cargo transportation safety and affect freight much. International shipping cost is very high and we need to consider and help for client.

Start your packaging journey with TinsPkg

Would you like more information about how TinsPkg could help produce custom tins for your product? Please fill out the form below or contact our office at (86) 0769-23156123 to speak with a packaging specialist. Thank you for considering TinsPkg Company!

Cell Phone

+86 15622936223

Call Us

(86) 0769-23156123

Address

No. 3 Xinnan Second Industrial Third Road, Qishi Town, Dongguan, Guangdong, China 523499

.jpg)

.jpg)