Hinged Lid Tin Containers Manufacturer

Our hinged lid tin box with hinge style come in a variety sizes and shapes. Each high-quality can is made from 100% food-grade and BPA-free materials. It’s a popular functional and decorative feature to ensure secure closure of box with a hinge mechanism connected lid and base. People would never loose the lid of tin box and recycle it as a storage box after.

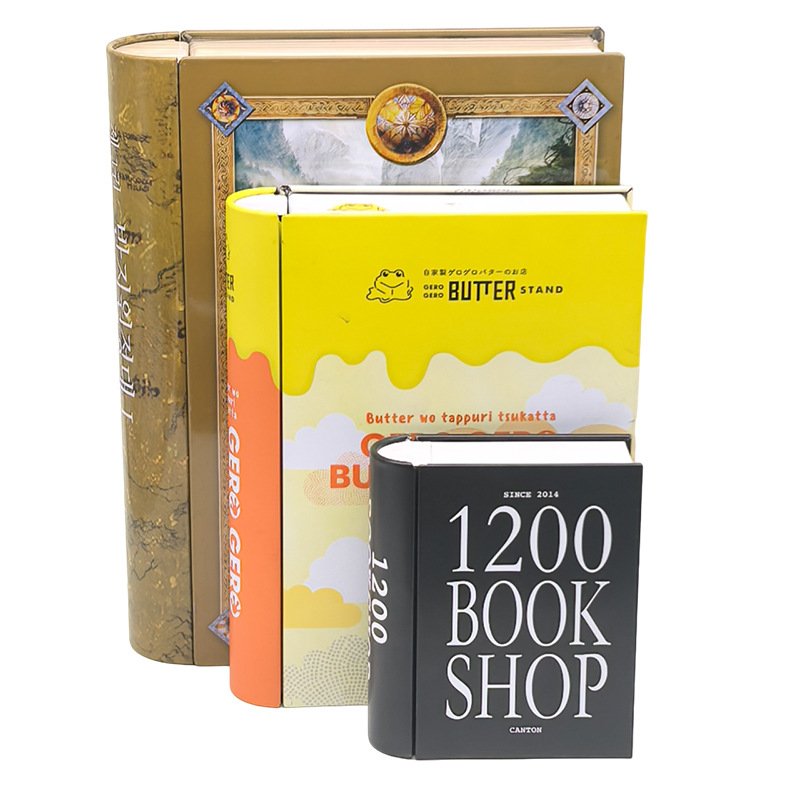

Hinged metal tin box are widely used for packing small candy mints, gift cards, color pencils, crayons, detergent powder, cookies, etc.

Hinged Lid Tin Containers Wholesale and Bulk

Tinspkg have available hinge tooling for different size tin box. For some tin mold without hinge tooling, we can customize and create a new hinge tooling for you with less cost and time. Our team have been helping lots of clients to realize their perfect packaging solution from the idea to on the shelf.

We Provide the Most Competitive Price for Worldwide Customers, 20% Lower Than Average Wholesale Price. We Are Honored to Export to 60+ Countries and Cooperate with 10000+ Customers Around the World.

And we are mainly specializing in custom printed metal tin box manufacturing. No matter you need full printing or logo ,pattern printing , logo customization, we all can meet your demand with competitive advantages.

Are You Looking for Hinged Lid Tin Containers for Your Brand or Wholesale Business? Tinspkg is Your Best Choice! We Will Assist You Throughout the Hinge Lid Tin Container Wholesale/OEM Process. 3000 Pieces(min. Order).

One-stop Solution for Complete Metal Tin packaging at Tinspkg

TinsPkg is committed to offering you a comprehensive solution that extends beyond the product itself. Our experienced team is dedicated to assisting you in crafting the ideal packaging tailored to your product’s needs.

About Material

Tin container packaging is a type of metal packaging that offers high durability and a variety of unique customizations, such as metallic reflection, varnishes, coatings, embossing and debossing, premium printing techniques, and textures. All of our tin products are made by high quality tinplate material with food grade printing and coating.

Tin Container Solutions To Your Industry

TINSPKG is a one-stop custom metal tin product supplier. We have produced thousands of types of tin container in different colors and capacities. We can provide customers with the best price and quality tin container.

- Area: 6000 Square Meters

- R&D engineers: 3 Staffs

- Tin Molds: 3000+ Sets

- Production Worker: 60+ Staffs

- QC Team: 7 Staffs

- Production Capacity: 2,000,000 PCS Per Month

- Machines:

- 110 Stamping Machines

- 5 Automatic Cutting Machines

- 6 Automatic Production Line

- 3 Packing Line

Please note: The right lists are only part of our Tin container. For more detailed types and specifications, Please Check Our Catalog or contact us.

What is a Hinged Lid Tin Container?

Hinged-lid Tin cans are often known as “flip-top cans”. The hinge is a mechanical device used to connect the box body and the lid and allow rotation between the two. The hinge assembly of the tin box may consist of a movable assembly or a foldable material. These types of tin boxes are sometimes reused to store items or to create kits, such as survival kit. A hobby involves modifying tin boxes with decorations and embellishments.

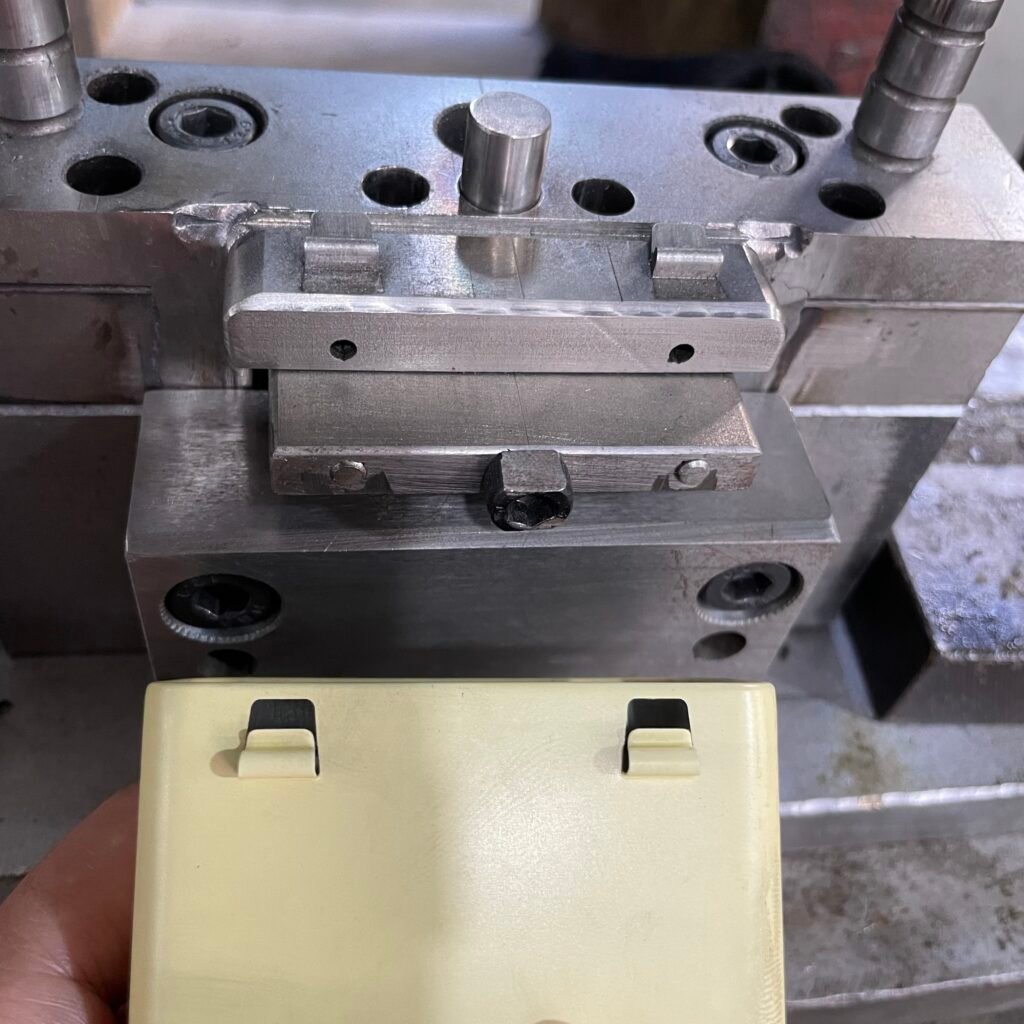

Tinspkg has available hinge tooling for different size tin box. For some tin mold without hinge tooling, we can customize and create a new hinge tooling for you with less cost and time.

How many kinds of hinged lids for Metal Containers?

Hinge lid keeps your box with lid together without lid being lost. It is regular feature for metal tin packaging boxes. There are 2 main hinge styles, and both of them are good choice.

No. 1 we call it window hinge- window hinge mold cost less and can modify add tooling based on removable lid tin mold, easy to assemble

No. 2 we call it metal bar hinge- metal bar hinge mold cost is higher than NO.1 as the process more than window hinge. Furthermore metal bar hinge needs to be assembled with one thin metal bar, labor cost. The metal bar thickness is around 0.8mm and 1.0mm

Appearance

No.1 window hinge lid is hard to stay up especially for medium size or large size tin box when you open it.

No.2 metal wire hinge can keep the hinge lid stays up when you open it

NO.1 window hinge Tin box production process and assembly

NO. 2 tin box with hinge production process and assembly by metal bar

The use of iron metal wire hinged lid and window hinged lid tin box

Iron metal wire hinged lid is mainly used for some small and medium-sized tins like custom pencil tin cases, chewing gum mint tins, Child resistant tin case, etc

The window-hinged lid is widely used for various sizes and shapes of tin containers no matter it is regular rectangular, square shape or irregular oval, heart, or other bespoke shape tins. From pocket tin box to large rectangular or other customized shape tins, it shows more creativity.

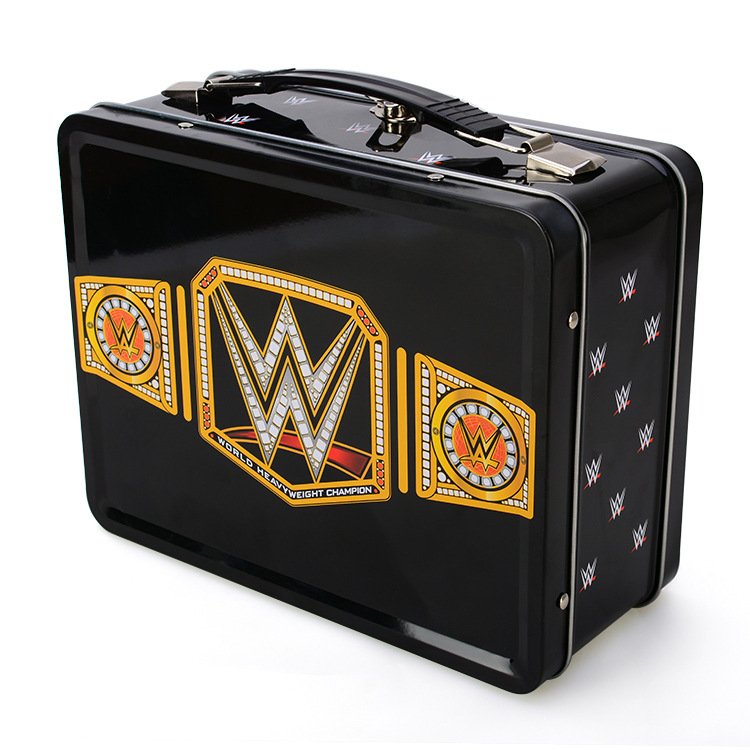

Lunch metal tin box with handle, gift store tin box, small tools packaging metal tin container, lip balm set tin case, brushes tin box, playing cards tin case, band aid tin box, sweets tin box, etc.

Tin Container Types

TinsPkg offers the ability to design your own unique cans, customized in different shapes, sizes, and colors according to the type of use. You can also choose your favorite construction method and lid, and add your unique logo and pattern on the surface of the can.