Procedure: step by step quality assessment

High-Quality Raw Materials

Material check: Tinspkg have been purchasing and sourcing tin plate or aluminum material from our reliable and trusted suppliers(Pacific Tinplate, Maanshan Iron & Steel, and Ansteel Tinplate) who can provide quality test report for the raw materials.

SGS Certified: All metal undergoes rigorous SGS testing. Tin plate must be crafted with high-grade tin or aluminum, must be food grade and free from harmful contaminants. This ensures safety, especially for food storage purpose.

Material thickness assurance: Gauge the metal’s thickness since this would impact durability. Generally material thickness more thicker, products would be more sturdier. The main thickness materials for tin plate ranges from 0.2 to 0.35mm, aluminum 0.3-0.5mm

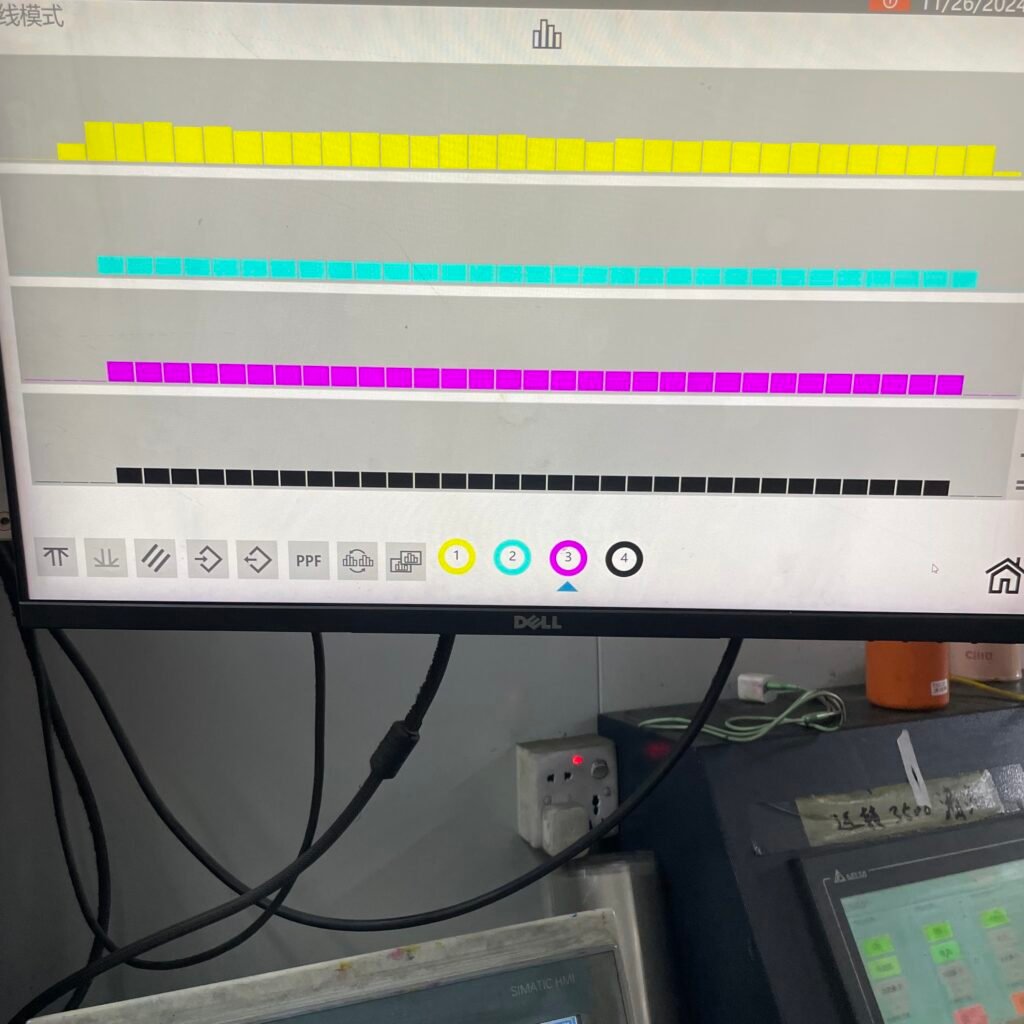

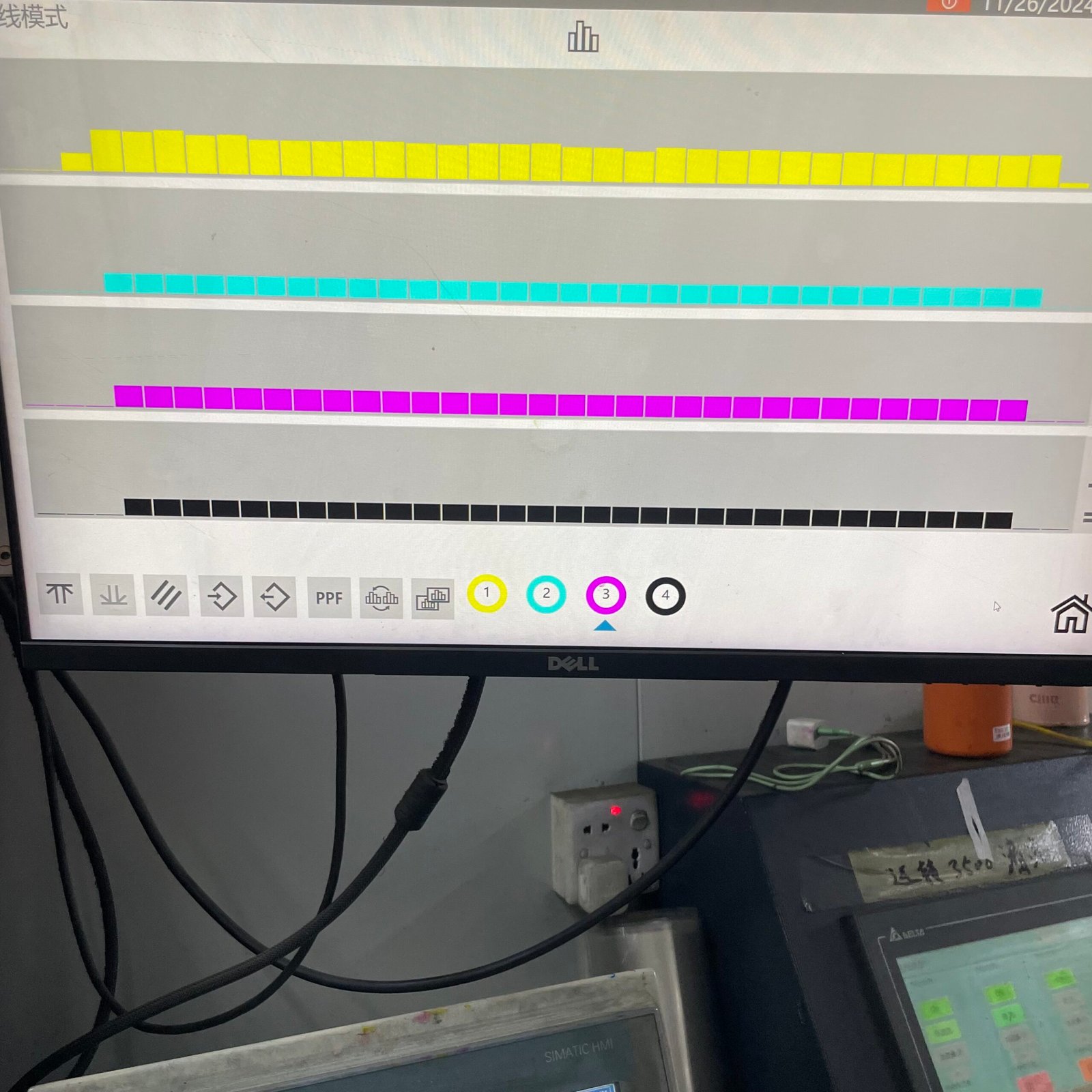

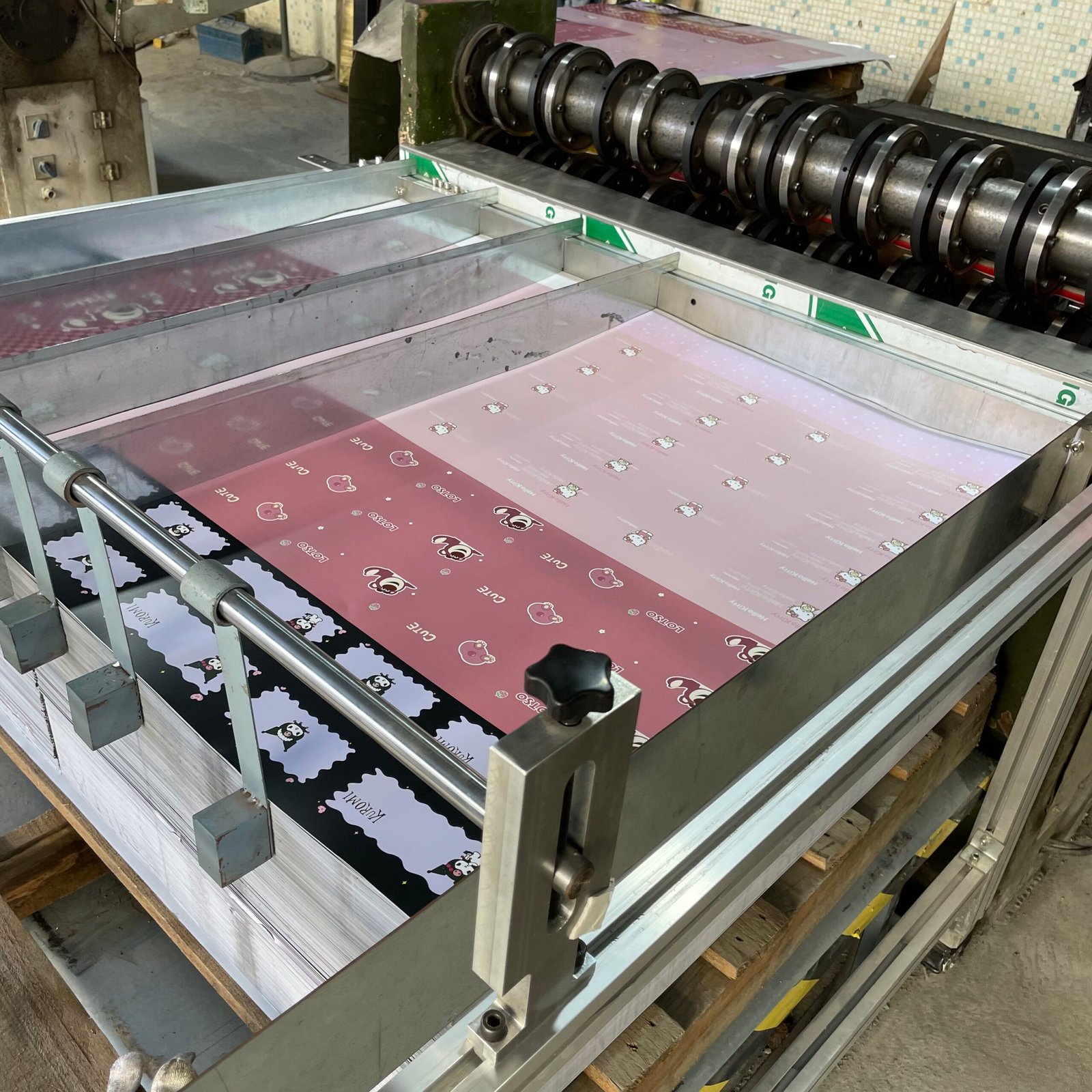

Evaluate printing and graphics

All printing ink and coating strictly follow domestic and internaltinoal food safety standards

Printing process quality and color check; clear and vibrant graphics. In addition, ensure the designs are aligned and have no blurring

Different industry application: we need to focus on printing especially such as high heat resistant requirement like hot wax, candle, balm pouring in. Other than that, for deep seamless tin, it requires special ink to printing in order to avoid ink fading after plate stamping

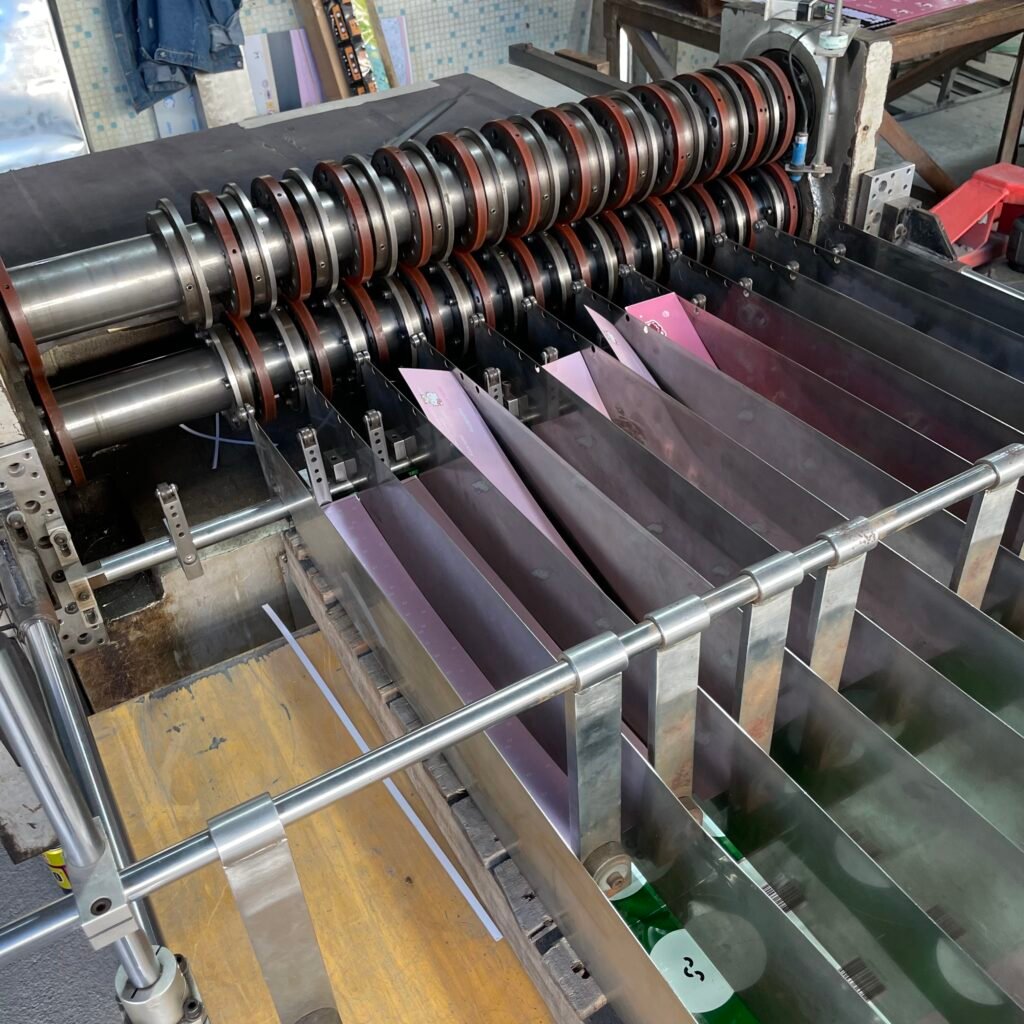

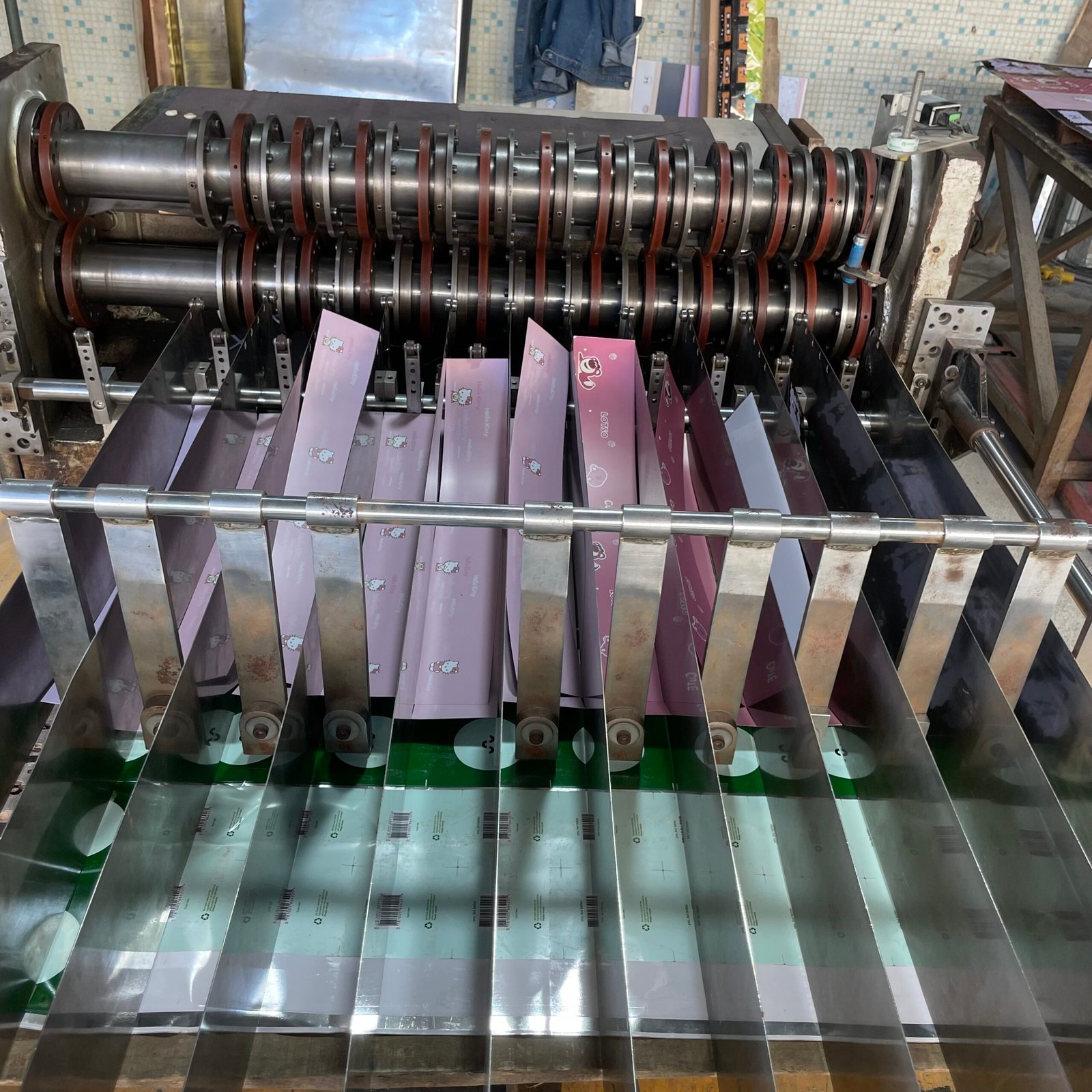

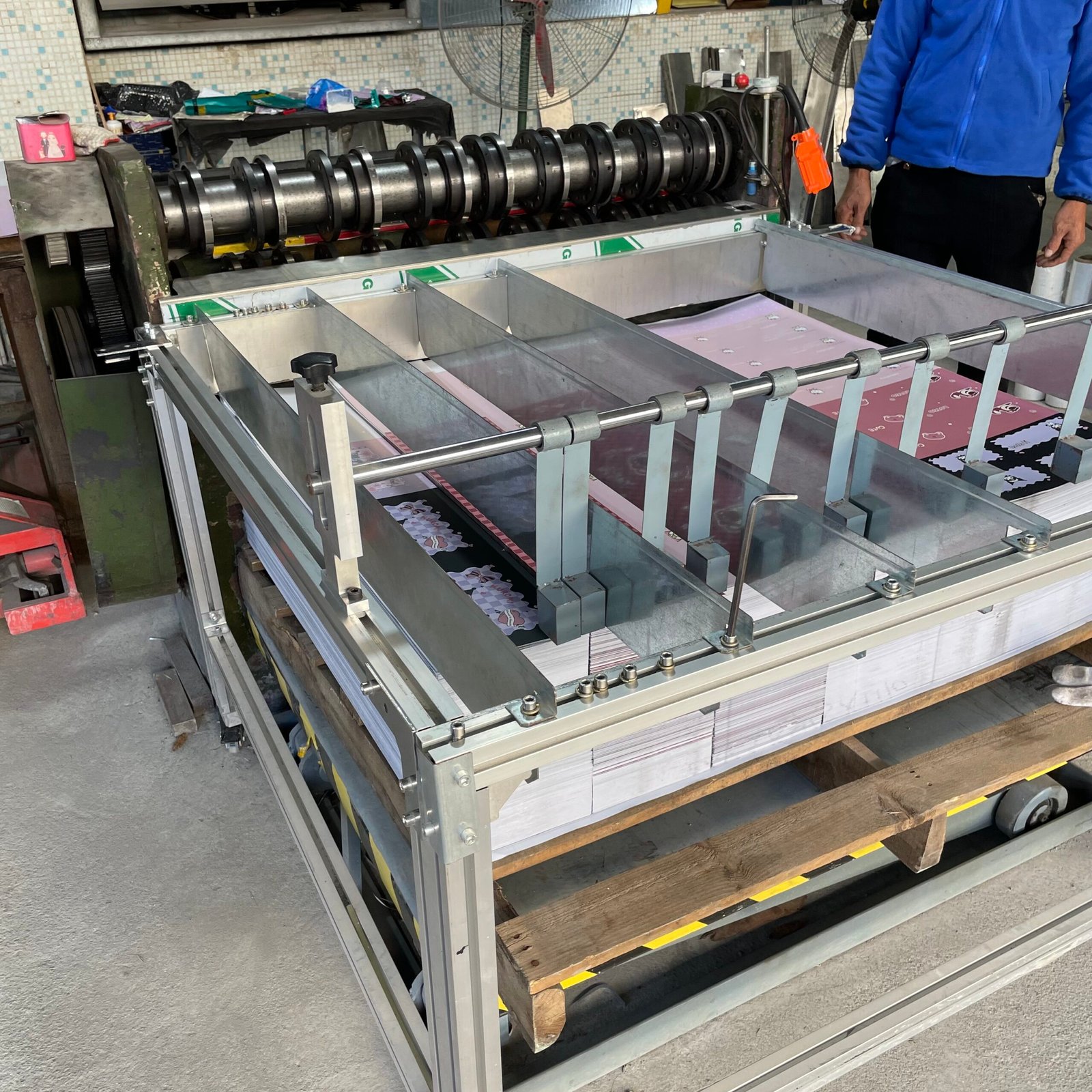

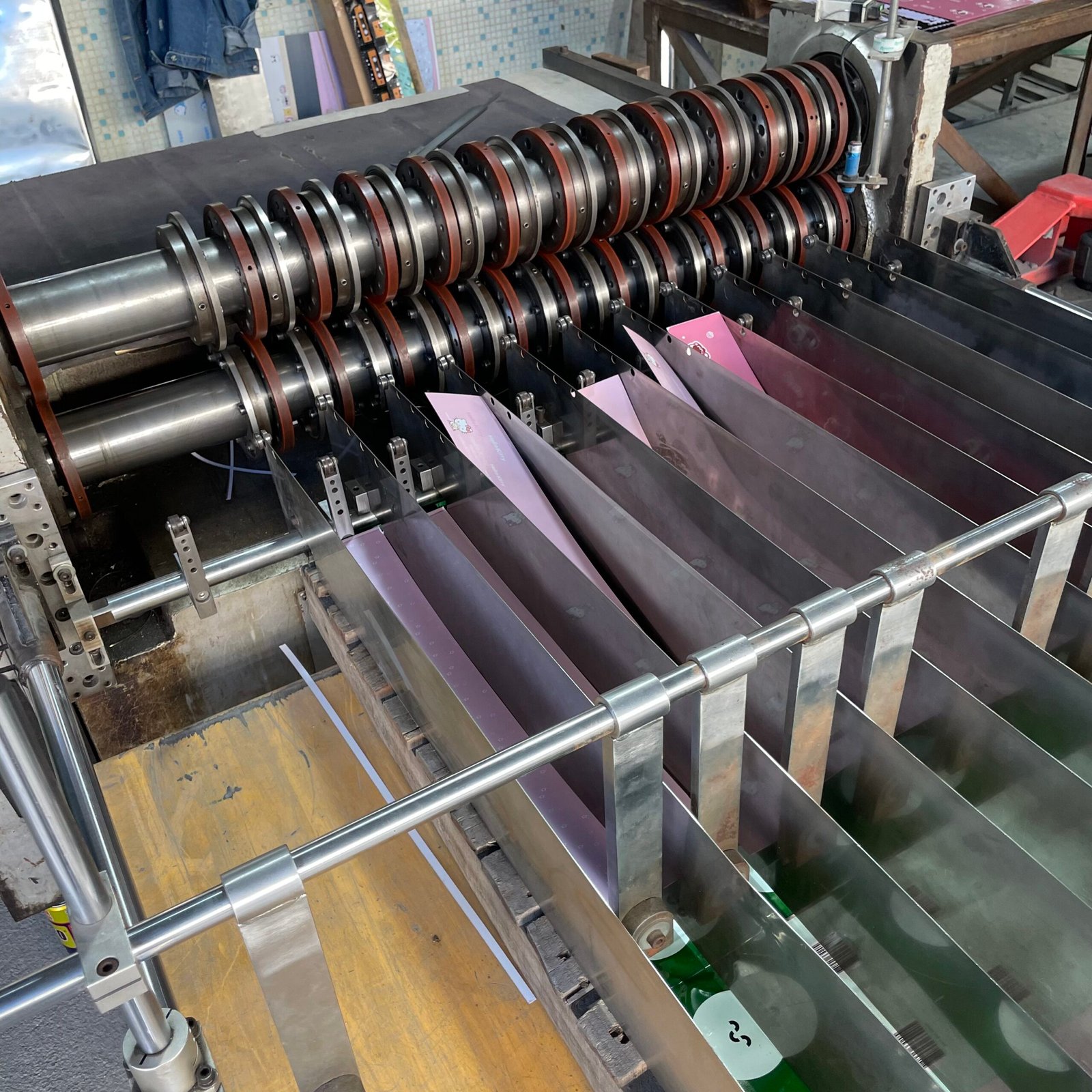

Quality assurance during tin plate cutting

Cutting process, we need to cut tinplate into correct size and without scratches to make sure the following production go smoothly

Shearing machines cut large-sized tinplate sheets into small sizes. A tin box is constructed by tinplate lid, tinplate body or tinplate bottom. If there are some errors in the size of tin sheet, it would affect tin can size and artwork position and lid tightness etc. Therefore, cutting correctly is the basis of tin can production.

The thickness of metal tin plate should be less than 0.35mm cutted by shearing machine. Or it would affect cutting quality and cause shearing machine damage. Tin plate would have irregular burrs that would affect production as well.

Tinspkg use a fully automatic shearing machine to complet this process and an engineer keep an eye on the shearing machine status.

In-Process quality assurance

One tin box completed requests many different processing molds. Therefore, fixing and modify each stamping machines with every mold and test is very important. These make sure good quality tin box with correct size, embossing accurateness, proper tightness, screw lid works, no scratches and no quality issues.

From the beginning of tinplate printing to cutting and mass production, every step we have rich experienced staff to check and control; production monitoring, during production check, initial production check, final random inspection and container loading supervision.

We must focus on and avoid below main quality issues happened during production:

Safety packing

Different tins we would pack in different ways. The main purpose is to make sure safety transportation and cut down shipping cost. You can find the main packing method from packaging solutions.

Our custom packaging design services cater to a wide range of products. Whether you’re looking for personalized cans, bottles, or jars, we’ve got you covered. All our packaging materials are crafted from sustainable and recyclable materials. You have the option to select one of our stock items and personalize it with custom-printed designs. Alternatively, we can assist you in creating a brand-new and unique custom packaging solution from scratch.