Custom Coffee tin containers

Tinspkg is a professional coffee bean metal tin can manufacturer. Our airtight tin cans are widely applicable for nuts & kernels, coffee beans walnut, sunflower seed storage. We produce a range of tin cans with screw top lid and degassing valve in rectangular,square or round shapes. All airtight tin can shall be 100% tested by automatic leakage detection equipment to avoid any micro leak. Good quality coffee bean tin can is with smooth cap, no smell and rust proof.

Why metal tins for coffee bean?

Food grade, Sealed and airtight

Made of non-reactive material, this tin won’t leave your coffee with any bitter, metallic taste. Many coffee tins come with airtight lids that help preserve the aroma and flavor of coffee by preventing exposure to oxygen, moisture and light. One-way air valve-the aroma of coffee remains intact. Keep your coffee beans and pantry essentials fresh and flavor with coffee bean airtight container. This multifunctional storage solution is designed with a large capacity to accommodate coffee beans, tea leaves, and more

Customizable, luxurious and durable

With full customizability, you can design your label, logo and artwork, ensuring your coffee tin cans stand out in the bustling coffee market. Tin cans are resistant to crushing, punctures, and external damage, ensuring the coffee remains intact during shipping and storage.

Eco-friendly, Reusable and Sustainable

Crafted from premium, eco-friendly and recyclable steel, tin cans are perfect for demonstrating your commitment to the environment. These cans are designed for reuse, reducing waste and leaving a positive mark on the planet. Space saving and easy to carry, perfect for home use

Coffee Tin Container Types

TinsPkg is one of China’s leading manufacturer and supplier of custom tin packaging, offering metal tin packaging customization and wholesale service. Over 11 years OEM and ODM metal tin packaging production experience, we are certified with ISO9001, BSCI, SGS. Metal tin box allows you to keep your coffee in bulk in a dry and closed place. Coffee tin container with various features to meet different demand.

Coffee Tin Container Wholesale and Customization

Tinspkg manufacture a range of coffee tins with different features. All of them can meet your versatile application. With a diverse portfolio of colors, designs and sizes, we creates wholesale coffee tins in different sizes. Utilizing top-grade, BPA-free, and recyclable tinplate, Tinspkg ensures a safe and reliable product.

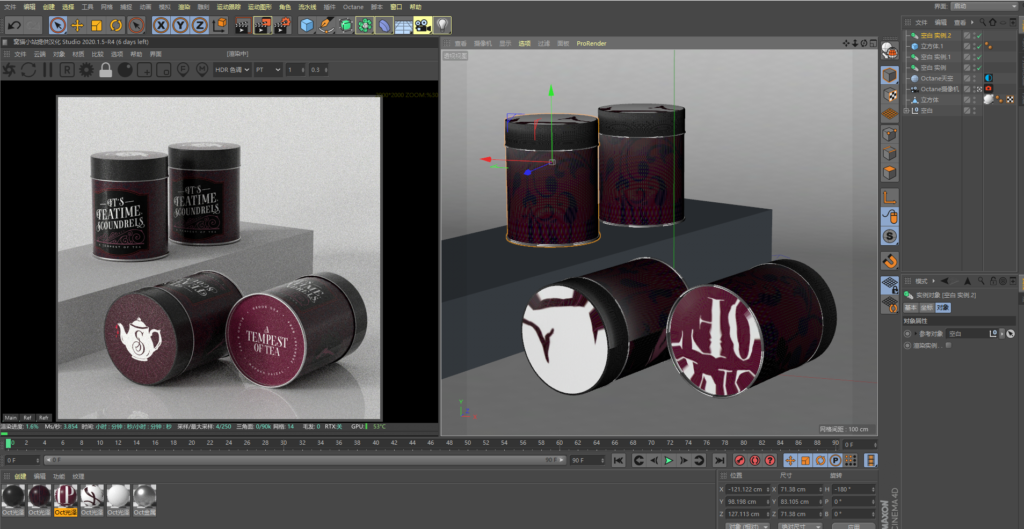

Pantone /CMYK Printing

You can customize tin box and tinplate products’ color according to the Pantone book as well as creating design by CMYK colors. The tinplate’s original color is silver. We can print in any color without limitation, offering full-color printing, solid Pantone/CMYK colors, and metallic Pantone/CMYK colors. You can choose from glossy (shiny) finish, matte finish, or a combination of both to meet your diverse needs.

Tinspkg proceed tinplate sheets offset printing by advanced printing machines Japan PRIMEX-P453. It helps to realize high-quality and stable printing quality.

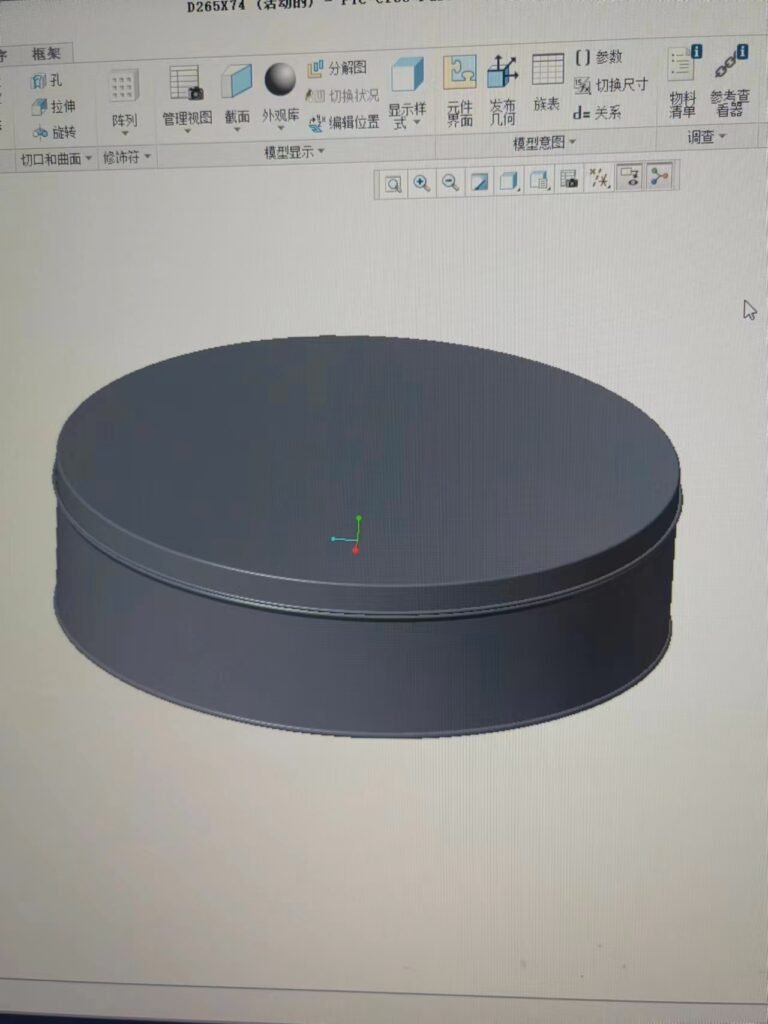

Customized Tins Size

Tinspkg have more than 2000 sets of various molds. You can choose our available molds from size and shape to customize your project which shall save your time and mold cost.

We can produce hermetic cans, airtight screw top tin can with one-way degassing valve, decorative coffee cans with latch lid or slip lid. Regular capacity for coffee range from 100g-500g, capacity of tins can be modified to meet different occassion.

We have more than 500 sets of molds for rectangular tins, over 480 sets of molds for round tins, 280 sets of molds for square tins, 30 sets of molds for oval shape tins, 23sets of molds for heart shape tins, 145 sets of molds for irregular shape tins, and 600 sets of molds for other tinplate products such as tin bucket, metal tin sign, tin tray, tin toy etc.

Our Product Specification

ITEM | Size | Thickness | Lid Type | Tin Shape | Material | MOQ(pcs) |

|---|---|---|---|---|---|---|

TSM1029 | 131x95xH186mm | 0.23mm | slip lid | rectangular | Tinplate | 3000 |

TSM1020 | 106x76xH188mm | 0.23mm | hinge lid | rectangular | Tinplate | 3000 |

TSM2009 | 90x90xH110mm | 0.23mm | slip lid | square | Tinplate | 3000 |

TSM3008 | D90xH155mm | 0.23mm | hinge lid | cylinder | Tinplate | 3000 |

TSM3008 | D90xH110mm | 0.23mm | slip lid | cylinder | Tinplate | 3000 |

TSM3023 | D74xH150mm | 0.23mm | slip lid | cylinder | Tinplate | 3000 |

TSM3019 | D65xH83mm | 0.23mm | slip lid | cylinder | Tinplate | 3000 |

Logo Embossing & Debossing

Dongguan Tinspkg Co.,Ltd helps companies create custom logo or pattern with embossed or debossed effect on tins to make your brand stand out. Embossing adds another level of texture and dimension to the box, giving it a truly luxurious feel. We can make flat embossing, 3D relief, debossing to elevate brand.

3D relief

3D relief adds phycial dimension, allowing custtomers to see and feel the embossed patterns 5-10mm height (logos, intricate designs, or textures on the surface of tinplate. Can be combined with printing designs and finishes for unique branding.

Flat embossing

Also called level embossing that creates a smooth, raised effect on tinplate surfaces without sharp edges or deep contours. It works seeamlessly with printing and coatings. Flat embossing produces a gentle elevation, maintaining a sleek, modern look while adding tactile inerest. Raised height would be 2-3mm generally.

Debossing

Debossing on tinplate to press a design into the tinplate surface, creating a recessed(indented) 3D effect. Unlike embossing, debossing adds subtle depth(2-3mm generally) and sophistication, often used for logos, text or intricate patterns.

Product Shapes

TinsPkg produce spice tins with an extensive array of customization options, including double-lidded spice tins, twist-off lug caps, transparent clear lids, plastic lids, magnetic bases, and more.

Accessories

There are versatile solutions for custom metal tin packaging, including not only printing, embossing, window features but also decorative add-on or accessories like clasp, beaded handle, plastic handle with latch lock, ball handle, metal clip lock etc. These make bespoke tin packaging absolutely adorable for storage and gift giving, perfect for carrying lunches, snacks, small toys, treasures, storing small accessories, makeup and stationery. Check below to find your customization preference

1. Beaded carry handle

Oval tote tin with beaded handle

Handle clasp and hinge

Beaded handle design great for carrying on-the-go items, snacks or toyscustomization preference

Beaded handle color customization

Other shape and size tins can be customized with beaded handle as well

2. Metal latch lock

Tins with an easy-to-use latch lock and an air-tight plastic seal is perfect storage solution for tea, coffee or dry products.

Versatility of reusable container with latch

Latch lock can be customized to match round or square tin container

Latch lock color can be silver or gold to meet your demand

3. Plastic lid with latch lock

Tins with an easy-to-use latch lock and an air-tight plastic seal is perfect storage solution for tea, coffee or Metal latch lock tin with plastic lid comes with an easy-to use latch and an air-tight rubber seal

Plastic lid shape, size and color can be customized to match your brand. It can be clear window lid as well.

4. Tin box with plastic handle and clasp

Tin box with plastic handle and clasp is widely regarded as lunch tin box or carry storage box.

Bespoke plastic handle color and size to match different tin box

Silver metal clasp popular choice

5. Ball handle

Ball handle is a decoration widely applied for round tin containers. It makes tin box lovely and attractive.

Ball handle can be customized into different material metal or plastic.

Ball handle color can be customized as well

6. Metal clip lock

Metal clip lock used for square or rectangular tin box

High quality metal click lock made by stainless steel

Size and thickness customized

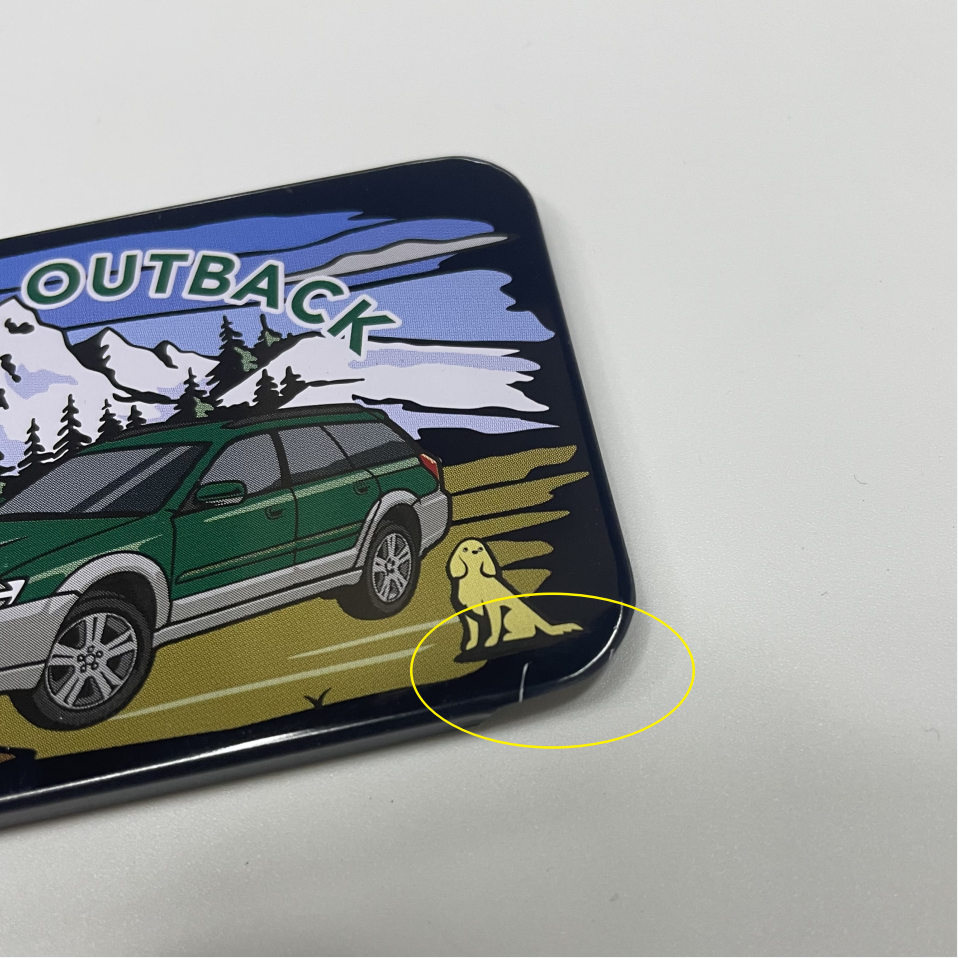

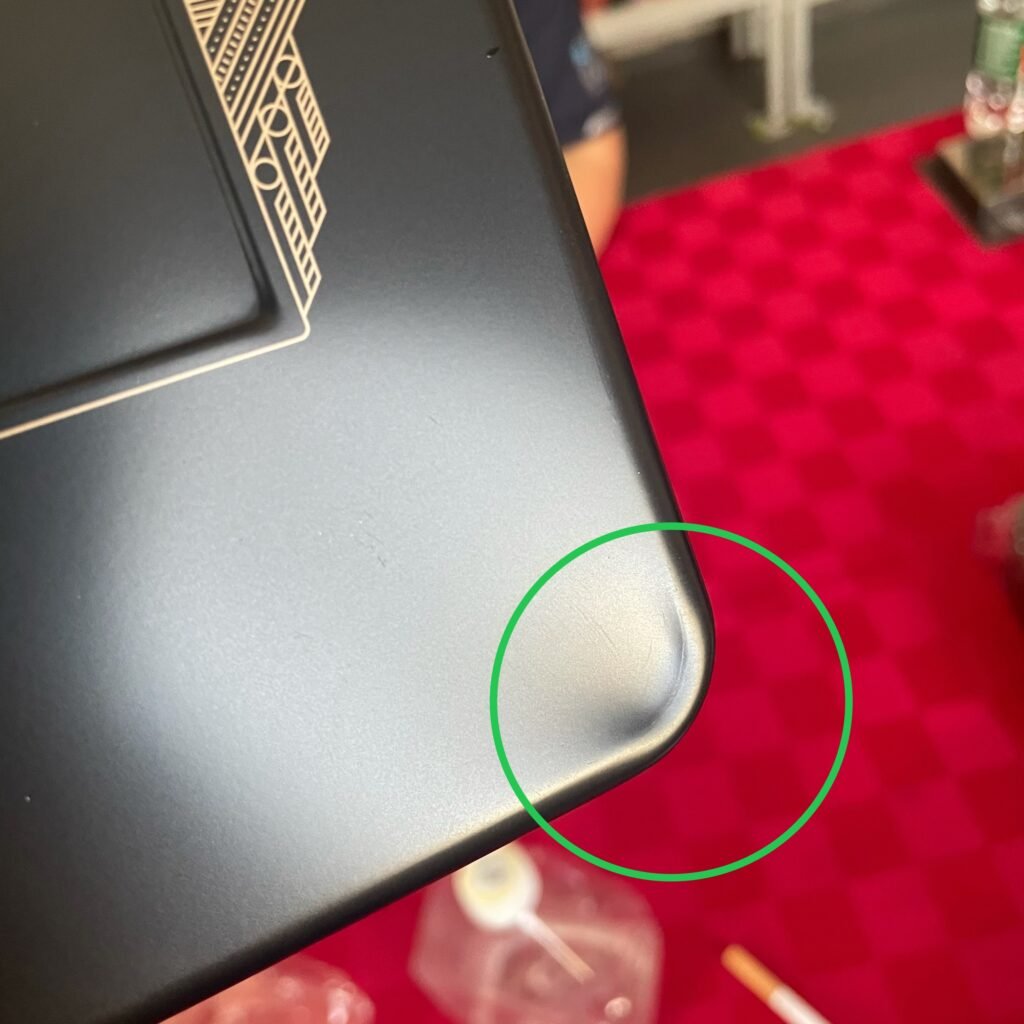

Custom Design Printing Quality Control Inspection

We strictly follow custom proof or pantone color on printing process to make sure your brand consistency.

The tinplate material Tinspkg use – All electrolytic tinplate coated steel sheet (including base plate) with SGS reports(REACH, RoHS)

Printing ink -JIANGMEN TOYO INK CO., LTD with EN71-3, PFAS, REACH SVHC REPORTS

The Process of Custom Coffee Tins

popular Coffee tins Box Bulk

Tinspkg produce a variety of styles and sizes tin containers for Tea and Coffee. All of mold support print and emboss customizations.

They are made of Food grade and 100% recycable metal tinplate that is perfect,decorative for storing coffee and Tea.

- Made of premium food grade tinplate with no edges; extremely sturdy and easy to clean.

- Made of non-reactive material, this tin won’t leave your tea with any bitter, metallic taste.

- metal tin with inner lids protects the contents from oxygen and light that can otherwise ruin both aromas and taste.

- Can be used for classification, collection, convenient and quick to be taken,

- Thick crack prevention, solid material, durable. A good choice for you.

- Ideal for storing pepper also fine herb, chocolate powder and other condiments as well.

- Space saving and easy to carry, perfect for home use as well as outdoor BBQ grill.

Tin Container Solutions To Your Industry

TINSPKG is a one-stop custom metal tin product supplier. We have produced thousands of types of tin container in different colors and capacities. We can provide customers with the best price and quality tin container.

- Area: 6000 Square Meters

- R&D engineers: 3 Staffs

- Tin Molds: 3000+ Sets

- Production Worker: 60+ Staffs

- QC Team: 7 Staffs

- Production Capacity: 2,000,000 PCS Per Month

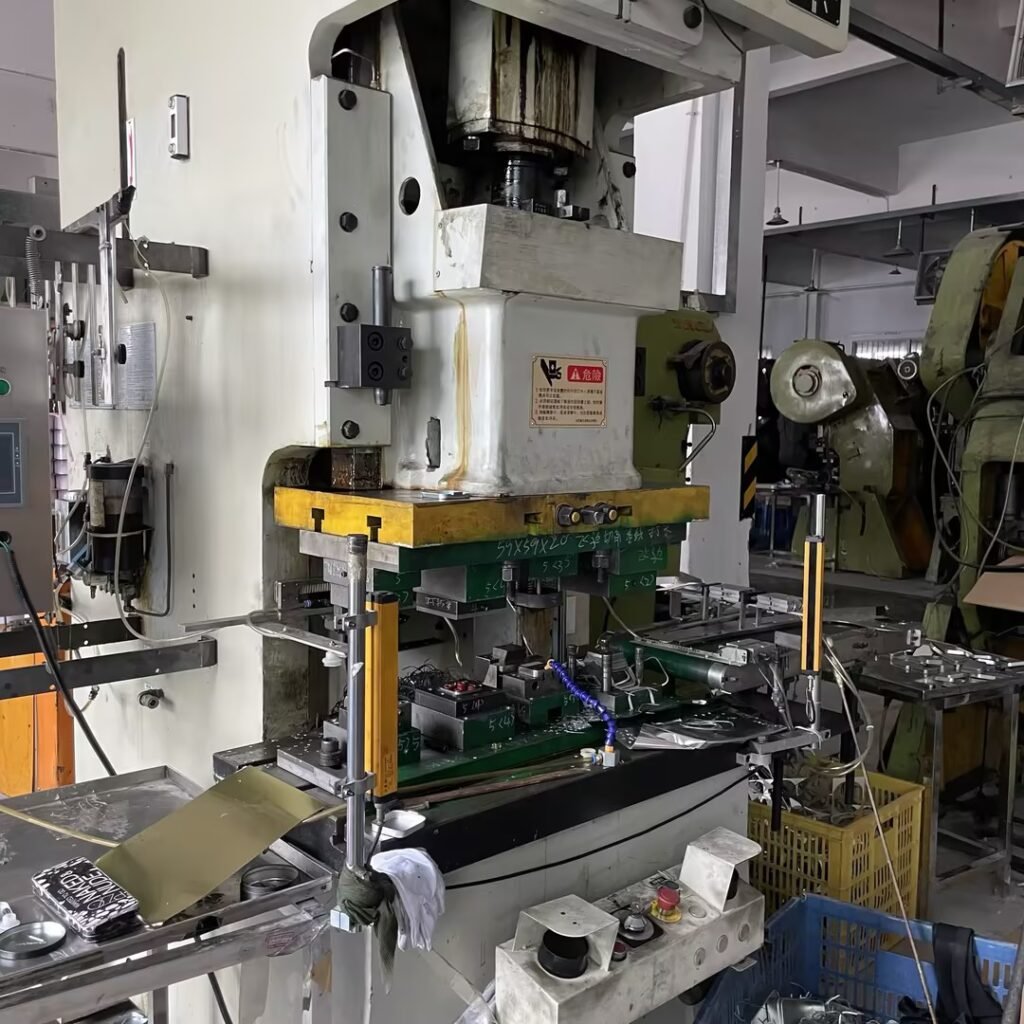

- Machines:

- 110 Stamping Machines

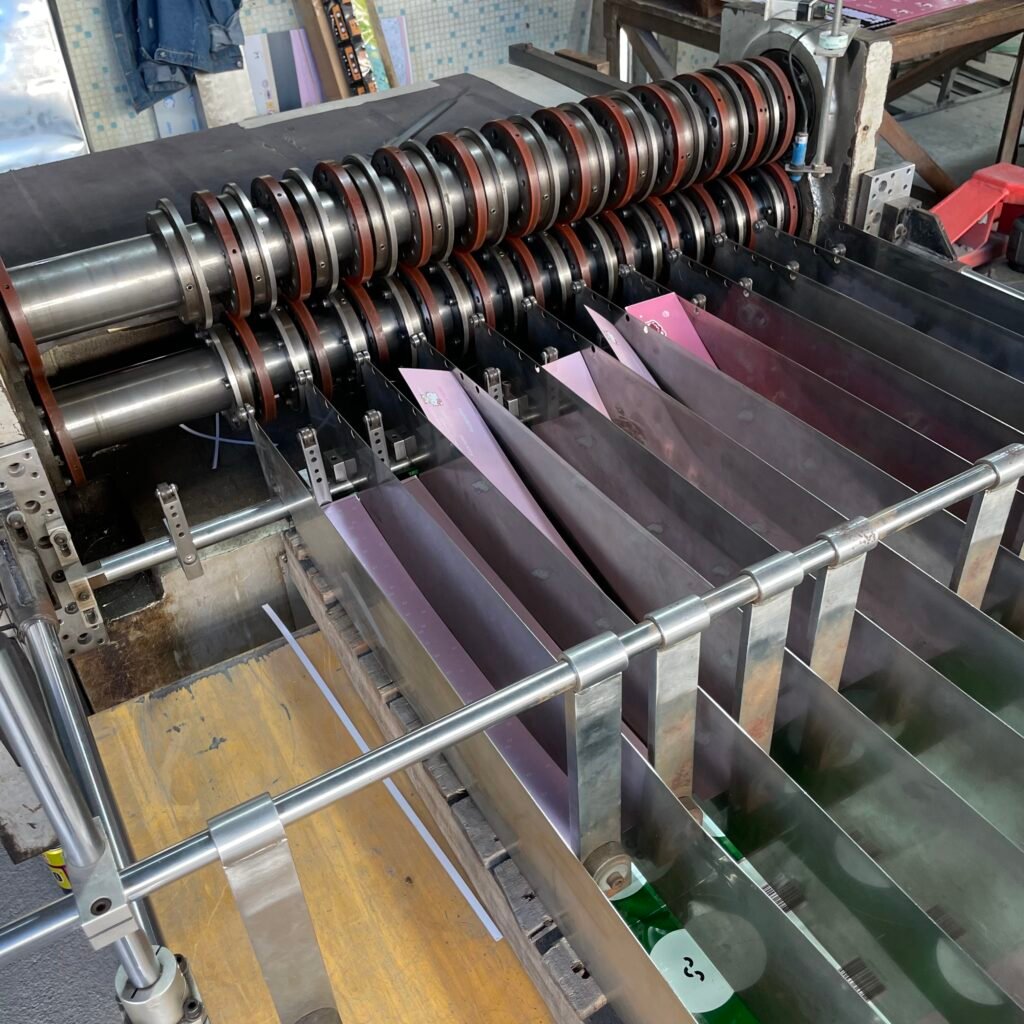

- 5 Automatic Cutting Machines

- 6 Automatic Production Line

- 3 Packing Line

Please note: The right lists are only part of our Tin container. For more detailed types and specifications, Please Check Our Catalog or contact us.

.jpg)

.jpg)