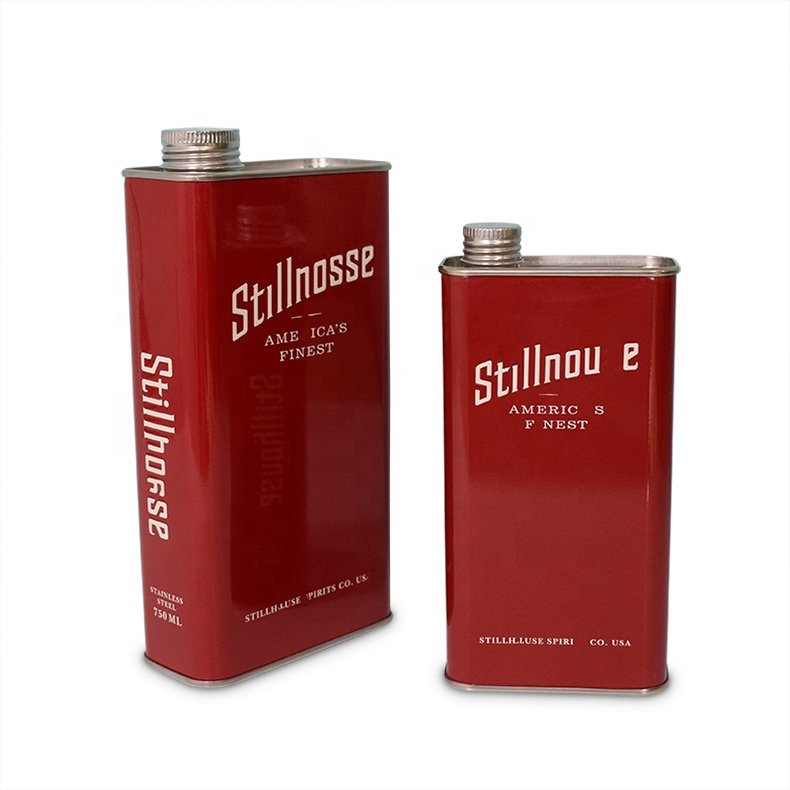

Custom olive oil tin Can

Tinspkg is established in 2013, we producing metal tin cans of various types and sizes catering to the needs of olive oil companies. Our high-quality oil tins are UN-approved for safe storage, available in sizes from 75ml to 5L with flexible closures. These tin can packaging are widely used for food oli like olive oil / cooking oil / colza oil / avocado oil / walnut oil / sunflower oil, groundnut oil, sesame oil etc.

Why metal tins for olive oil?

Protection and freshness

Tin cans block light, oxygen, and moisture, which helps prevent oil oxidation and rancidity; extended shelf life than plastic bottles.

Automatic leak detection – each metal can will be requested to tested to ensure the can quality.

Durability and food-grade quality

Unlike plastic or glass, tin cans don’t break easily, more rigid and impact-resistant to transport.

Complies with FDA/EU food safety standards. Food-grade lacquer coatings prevent interaction between oil and metal.

Branding and customization

Printing customization on surface of tin can by high-quality offset printing including logos, product information, nutrition facts.

Versatile closure types to be customized – spout caps, pump sprayers, pull-out closures for easy pouring.

Premium look compared to plastic jars.

Food oil Can Types

olive oil Can Wholesale and Customization

Tinspkg manufactures a range of oil tin cans that are applicable for olive oil/cooking oil/colza oil/avocado oil/walnut oil/sunflower oil/groundnut oil, sesame oil, etc. Oil can be filled from 75ml to 1 Liter to meet different demand and the height of tin can mold could be modified. One-stop solution for your oil cans customization with us!

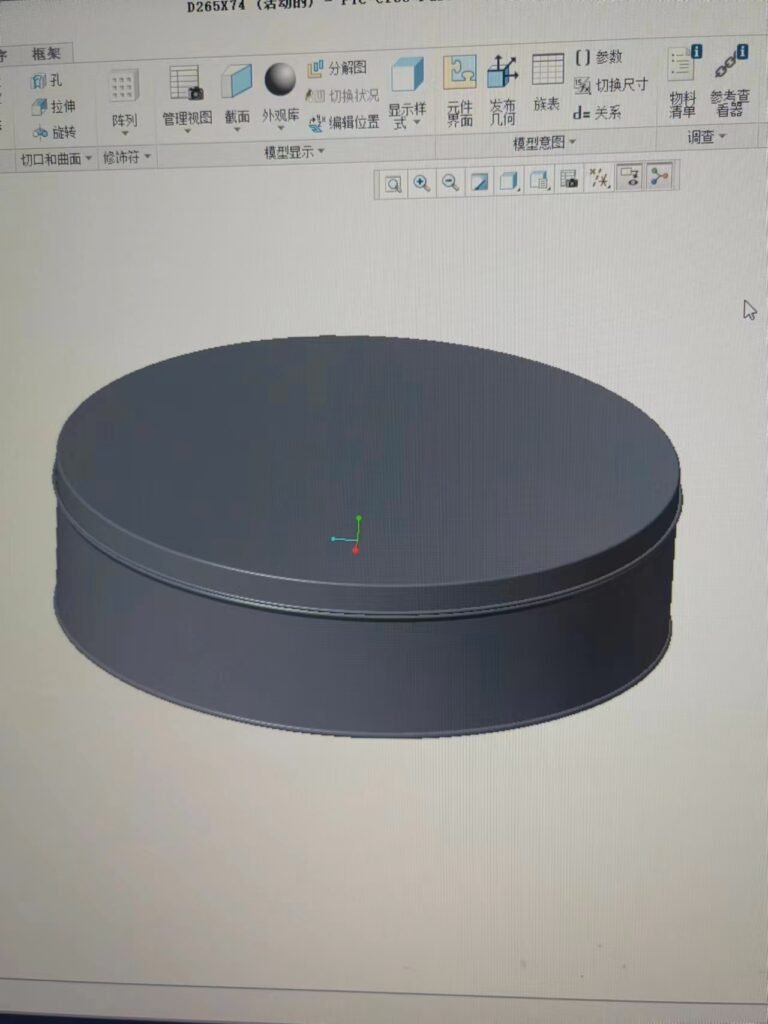

Customized Tins Size

Tinspkg has more than 2000 sets of various molds. You can choose our available molds from size and shape to customize your project which shall save your time and mold cost.

We can produce 75 ml -1 liter oil can in F-type and round shapes. These tin cans can be customized with printing as per your design and with various lid types.

We have more than 110 sets of molds for oil cans in rectangular and round shapes. All of our oil tin can heights could be modified to hold different volumes. All of oil tin cansare made from 0.23-0.28 mm thickness premium tinplate with 2.8g/m² tin coating to make sure each tin high quality standard.

Our Specification

ITEM | Capacity | SIZE | THICKNESS | LID TYPE | TIN SHAPE | MATERIAL |

|---|---|---|---|---|---|---|

TS7103 | 1 Litre | 106x55xH228mm | 0.28mm | Plastic Cap | F-Type | Tinplate |

TS7105 | 1 Litre | 96x70xH190mm | 0.28mm | Plastic Cap | F-Type | Tinplate |

TS7101B | 1 Litre | 116x60xH175mm | 0.28mm | Screw top/ pump sprayer | F-Type | Tinplate |

TS7302 | 250ml | D75xH143mm | 0.28mm | Plastic Cap | Cylinder | Tinplate |

TS7301 | 250ml | D67xH113mm | 0.28mm | Plastic Cap | Cylinder | Tinplate |

TS7108B | 250ml | 77x55xH110mm | 0.28mm | Plastic Cap | F-Type | Tinplate |

TS7108 | 250ml | 77x54xH110mm | 0.28mm | pump sprayer | Cylinder | Tinplate |

TS7107 | 380ml | 102x46xH120mm | 0.28mm | Plastic Cap | F-Type | Tinplate |

TS7106 | 500ml | 100x62xH120mm | 0.28mm | Plastic Cap | F-Type | Tinplate |

TS7303 | 520ml | D65xH163mm | 0.28mm | Plastic Cap | Cylinder | Tinplate |

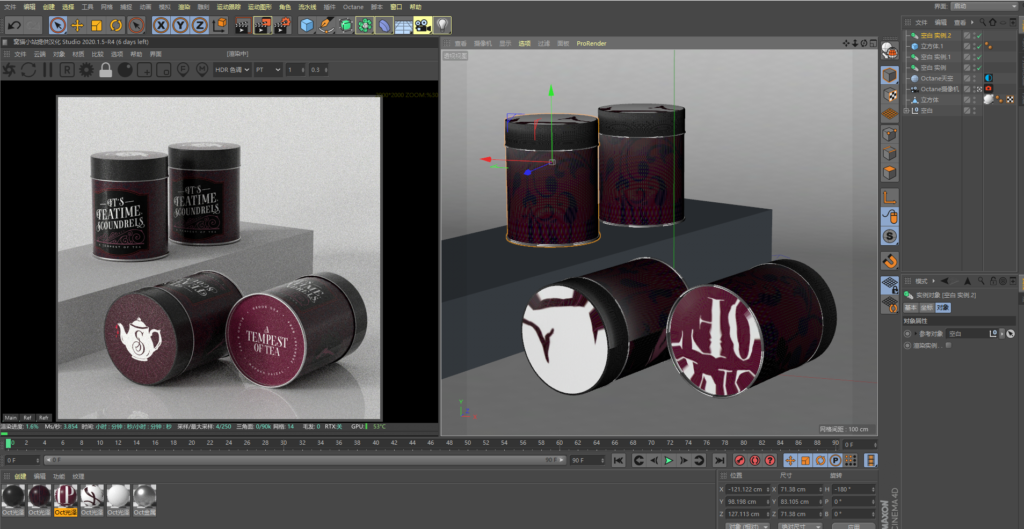

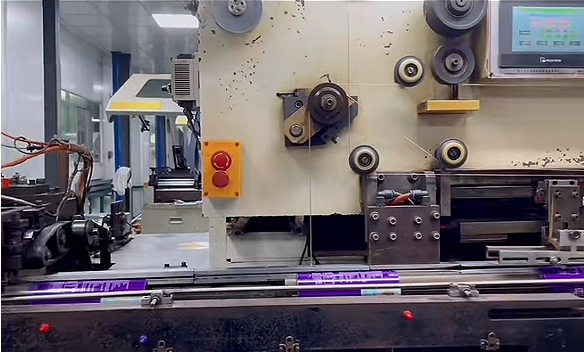

Pantone/CMYK Printing

You can customize tin box and tinplate products color according to the Pantone book as well as creating design by CMYK colors. The tinplate original color is silver. We can print any color / any pattern without limitation; full colorful printing, solid Pantone /CMYK color, metallic Pantone /CMYK color and get them by glossy(shiny) finish, matte finish or combine matte with glossy finish to meet your diversity needs. Tinspkg proceed tinplate sheets offset printing by advanced printing machines Japan PRIMEX-P453/453. It helps to realize high quality and stable printing quality.

Inner coating – Epoxy-Phenolic Resin (gold laqure) and clear lacquer are the most common for edible oil cans, strong resistant to oil and fats, preventing corrosion and flavor migration.

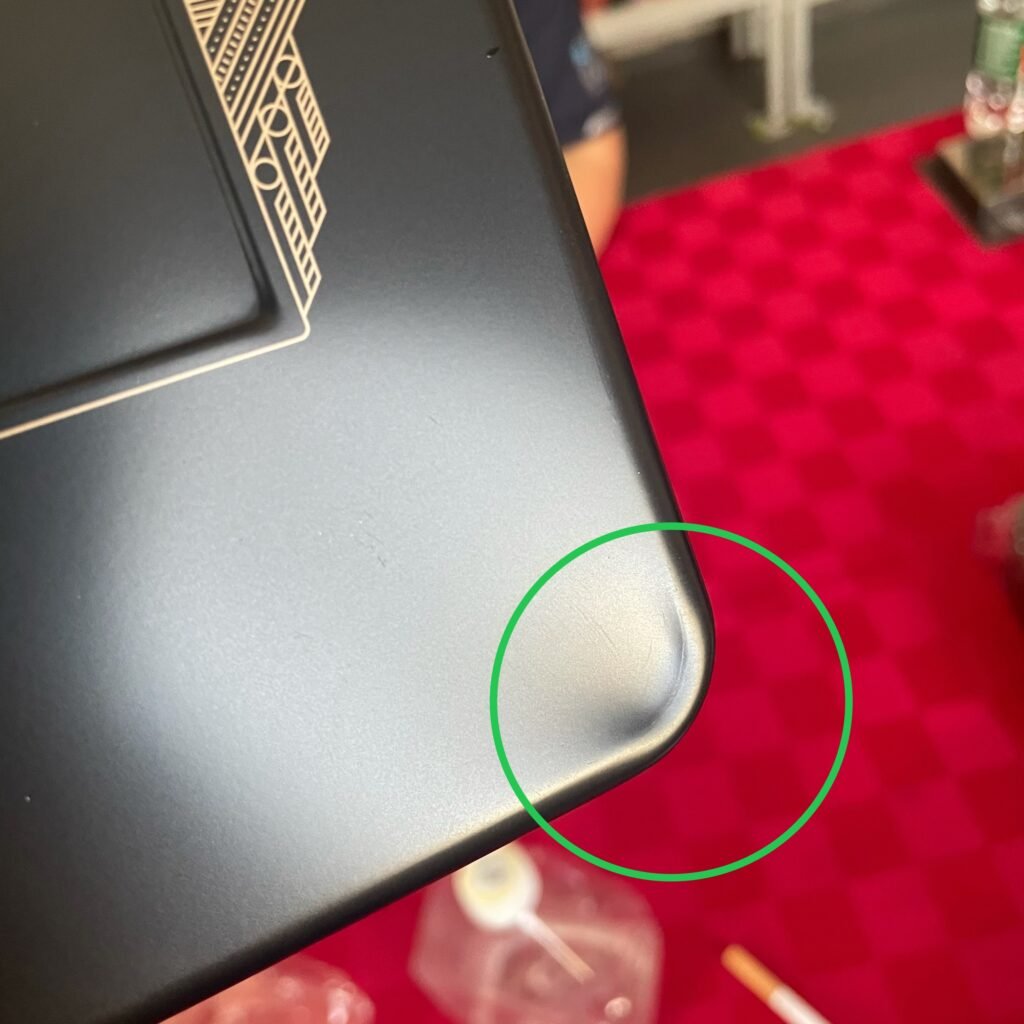

Logo Embossing & Debossing

Dongguan Tinspkg Co.,Ltd helps companies create custom logo or pattern with embossed or debossed effect on tins to make your brand stand out. Embossing adds another level of texture and dimension to the box, giving it a truly luxurious feel. We can make flat embossing, 3D relief, debossing to elevate brand.

3D relief

3D relief adds phycial dimension, allowing custtomers to see and feel the embossed patterns 5-10mm height (logos, intricate designs, or textures on the surface of tinplate. Can be combined with printing designs and finishes for unique branding.

Flat embossing

Also called level embossing that creates a smooth, raised effect on tinplate surfaces without sharp edges or deep contours. It works seeamlessly with printing and coatings. Flat embossing produces a gentle elevation, maintaining a sleek, modern look while adding tactile inerest. Raised height would be 2-3mm generally.

Debossing

Debossing on tinplate to press a design into the tinplate surface, creating a recessed(indented) 3D effect. Unlike embossing, debossing adds subtle depth(2-3mm generally) and sophistication, often used for logos, text or intricate patterns.

Accessories

Tinspkg’s oil tin cans with various types of closure for option. You can choose plastic pump sprayer, plastic flip cap, plastic screw cap with plug interior, plastic spout cap and other customized closure types. All these plastic caps are made from food-grade plastic materials that are safe for contact with edible oil, resistant to leakage, and strong enough to withstand handling. They are mainly made from:

- HDPE (High-Density Polyethylene): strong, rigid and resistant to oil penetration; FDA/EU approved for food contact.

- PP (Polypropylene): good chemical and heat resistance; often used for screw caps and spouts that provides a tight seal with flexibility

flip cap

Plastic flip-top cap makes edible oil tin can easier to open, pour, store and re-close while maintaining freshness and reducing leakage. It allows consumers to open and close the can easily without needing a separate opener, prevents oil from spilling or dripping compared to a fully open tin mouth. It comes with an inner seal or tight snap fit, helping to avoid oil leakage during transport and storage. It’s preferred design for household and 500ml or less oil tin can. The spout inside the flip cap provides a controlled stream of oil, making it easier to pour the right amount for cooking without waste.

plastic pump sprayer

A plastic pump sprayer on edible oil tins make oil usage more precise, cleaner, healthier, turning the tin into a user-friendly, portion-control dispenser. It helps apply just the right amount for health and diet benefits, reducing waste. It is convenient by one-hand operation, easy to spray without lifting or tilting a heavy tin can, and reduce direct contact with oil inside the tin. It ensures oil is spread evenly over pans, grills, baking trays, or food that improves cooking results. Plastic pump sprayer oil tin can is suitable for home kitchens, restaurants, and catering services.

plastic spout cap

Plastic spout cap (pull-out spout closure) makes it easy to pour oil without removing the entire lid and the spout is hidden inside the closure, can be pulled out when needed. It’s reclosable and airtight. Many pull-out spout closures have a breakable ring or seal, ensuring the product hasn’t been opened before purchase.

It has excellent air tightness and workable for any size oil tin can from 0.5L to 5L. And this kind of cap can be applied by automatic capping machines on the tin production lines.

screw cap with plug interior

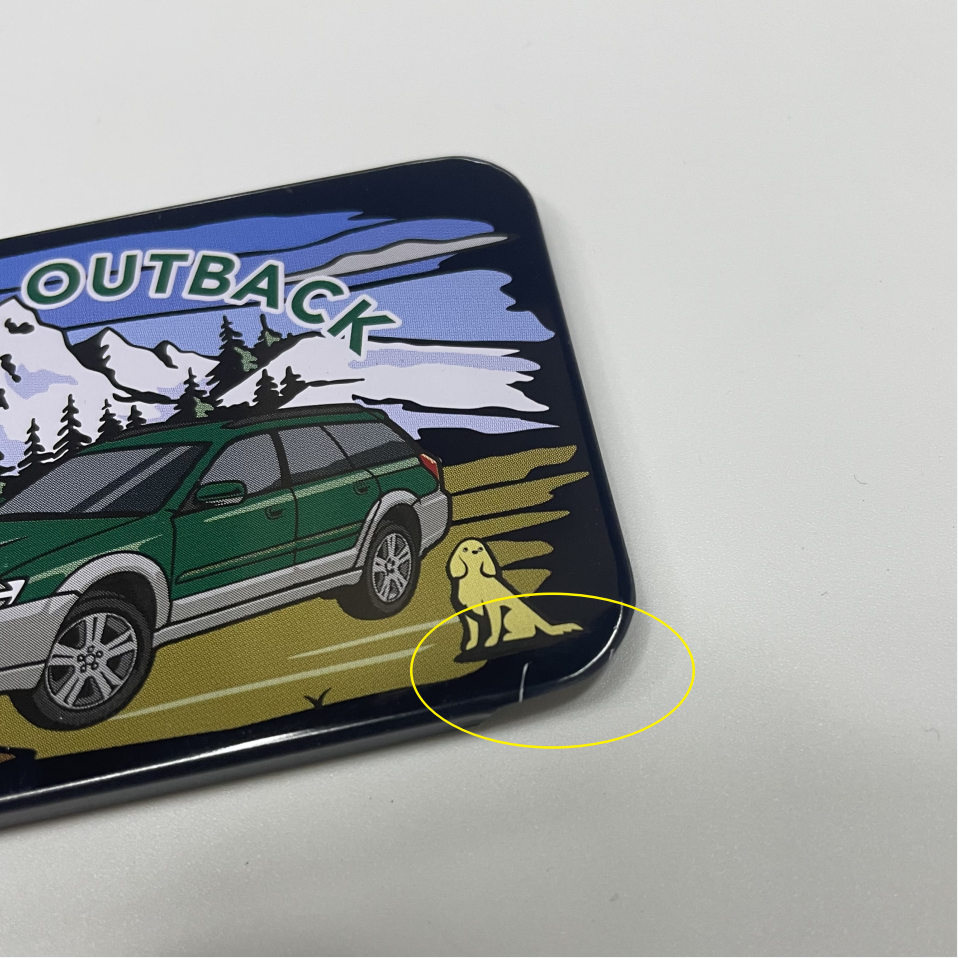

Custom Design Printing Quality Control Inspection

We strictly follow custom proof or pantone color on printing process to make sure your brand consistency.

The tinplate material Tinspkg use – All electrolytic tinplate coated steel sheet (including base plate) with SGS reports(REACH, RoHS)

Printing ink -JIANGMEN TOYO INK CO., LTD with EN71-3, PFAS, REACH SVHC REPORTS

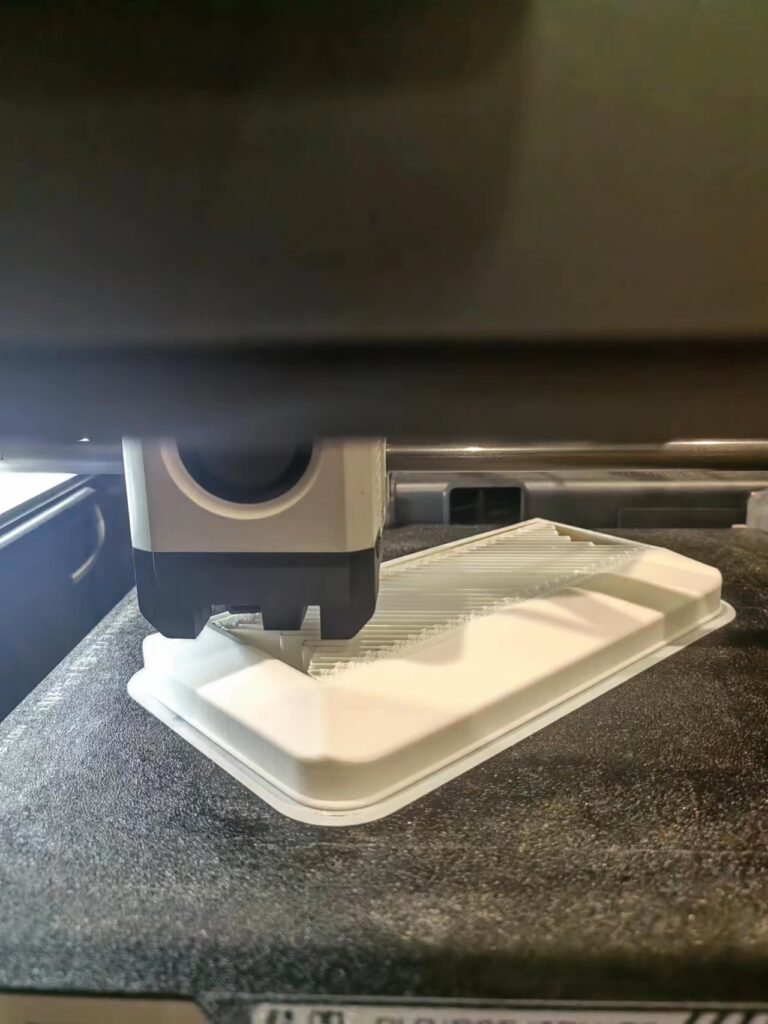

The Process of Custom olive oil Can

popular olive oil Can Bulk

Tinspkg manufacture seamless candle tins, candle tins with easy open lids, aluminum candle jars; and offer a wide range of high quality empty candle tins in various sizes and capacities to meet the needs of our customers.

From small 1 oz tins to larger 16 oz containers, we have a size to fit every requirement. Our most popular sizes include 2 oz, 4 oz, 6 oz, 8 oz, 10 oz and 16 oz tins. In addition, we make candle tins in various shapes including round shaped candle tins, square shaped candle tins, bowel shaped candle jars, flower shaped candle jars. And you can customize your candle tins with your artwork printing by the perfect finishing touch for your brand.

Except for full customization, you can choose from our selection of colors, including black, gold, white, and rose gold, and customize them with your artwork or logo. And you can add paper stickers to your empty tins for a more budget-friendly option. No matter what your needs or budget are, we have a solution for you.

Our Product Model

What is Metal tin can for Olive oil?

Olive oil tin can is a specialized food-grade packaging solution designed to preserve the quality, freshness and flavor of olive oil, walnut oil, cooking oil and any other edible oil while providing an attractive, durable, and sustainable container. These cans offer a range of benefits for both producers and consumers of edible oil.

What is olive oil tin metal can made of?

Olive oil tin can is made from low-carbon steel coated with a thin layer of tin. The thickness of the tinplate varies according to the size of the container. The size of the container is larger, the tinplate request more thicker generally 0.23-0.28mm thickness. Tinspkg usually produces edible oil tin can by 0.28mm thickness to ensure durability. Tinplate is food-grade and FDA-compliant for edible oils and any other dry foods.

Why you should use olive oil tin can for your olive oil factories or brands?

Olive oil is extremely sensitive to light, oxygen, and heat. Metal tin cans block 100% light, better than glass. And it reduces oxidation, preserves flavor, aroma, antioxidants and shelf time.

Tin cans help prevent rancidity and make oil stay fresh longer during storage and shipping, lower risk of leakage or breakage.

Olive oil tin cans can be manufactured with FDA food contact compliance, EU regulation EC1935/2004, BPA-Free / BPA-NI internal coatings. This makes tin can idea for overseas export markets.

It’s strong and impact-resistant, lower breakage than glass. And stackable for pallets and containers, ideal for bul and retail formats. Retail size varies from 100ml, 250ml to 500ml. For food service or bulk, we recommend 1L/1.25L/1.5L/2L/2.5L/3L/3.5L/4L/5L. The height of our tin can all can be customized to hold different capacities of olive oil.

Tin cans would help your edible oil brands meet eco-friendly positioning and retailer requirements. Metal tin cans are 100% recyclable, long life cycle, lower environmental impact than single-use plastic.

Our olive oil tin cans are with various types of closures(easy-spouts, anti-drip caps, tamper-evident closures) that is convenient for end consumers, clean pouring, less oil waste, and a better kitchen experience.

Furthermore, another important reason is that olive oil tin can be customized with premium brand image, with high design flexibility and strong storytelling features to expand your brand’s influence.

How do you use olive oil tin can?

Different edible oils have different sensitivity, price positioning, and usage, so the tin structure, coating, and format should match the oil type.

Olive oil (extra virgin/virgin/pure) is highly sensitive to light and oxygen; we recommend tinplate with food-grade internal lacquer, BPA-free coating, cylinder or rectangular shape (250ml -5L) with optional pour spout and typical markets are EU, USA, Middle East.

Avocado oil is light-sensitive, high-value, health-focused and often cold-pressed. We usually recommend small to medium sizes, 250ml-1L, high-end printing/matte finish that protects nutrients and matches premium branding.

Coconut oil is stable but solidifies below ~24°C, often used for cooking or skincare. We recommend wide-mouth round tin can, tinplate with oil-resistant lacquer, and easy-open or screw lid. As it is easy to scoop when solid and durable for multi-use environments.

Sunflower oil, soybean oil and corn oil are mass-market, price-sensitive, high-volume consumption. We recommend standard tinplate can in large sizes(1L-5L) with cost-efficient coating.

Canola, rapeseed oil is mild flavor and is common in industrial kitchens. We recommend 3L-5L popular sizes that are stackable, efficient for storage and transport.

Peanut oil has strong aroma, oxidation-sensitive. We recommend mid to large sizes (1L-5L).

Sesame oil is strong aroma, often sold in small volumes. We recommend rectangular or round tins in 250ml -500ml.

How to reuse your empty olive oil tin can?

We would recommend people to reuse olive oil tins to refill with bulk olive oil. And it’s great to go picnic with this reused olive tin can. If reuse is no longer needed, just fully clean the tin and place it in metal recycling.

How to find reliable olive oil tin can supplier

Olive oil brands, producers and retailers must source the right tin can supplier. Tin can packaging not only preserves quality but also reflects your brand image.

Tinspkg meets FDA food contact compliance for U.S. export, EU regulation EC 1935/2004 compliance, migration test reports for fatty foods, BPA-free internal coatings. Internal lacquer resists oxidation and oil acidity, no flavor contamination.

Our in-house quality check ensures stable wall thickness and seam integrity, low defect rate, clean production environment. And we provide full customization and branding options(including size, shape, printing and embossing. Tinspkg has rich experience with shipping to US, EU and other international markets. Tinspkg shall be a trusted partner for olive brands, producers, and retailers worldwide.

Tin Container Solutions To Your Industry

TINSPKG is a one-stop custom metal tin product supplier. We have produced thousands of types of tin container in different colors and capacities. We can provide customers with the best price and quality tin container.

- Area: 6000 Square Meters

- R&D engineers: 3 Staffs

- Tin Molds: 3000+ Sets

- Production Worker: 60+ Staffs

- QC Team: 7 Staffs

- Production Capacity: 2,000,000 PCS Per Month

- Machines:

- 110 Stamping Machines

- 5 Automatic Cutting Machines

- 6 Automatic Production Line

- 3 Packing Line

Please note: The right lists are only part of our Tin container. For more detailed types and specifications, Please Check Our Catalog or contact us.